Measuring Circularity: Metrics for a Sustainable Fashion Future: New Standards

Material Circularity Metrics

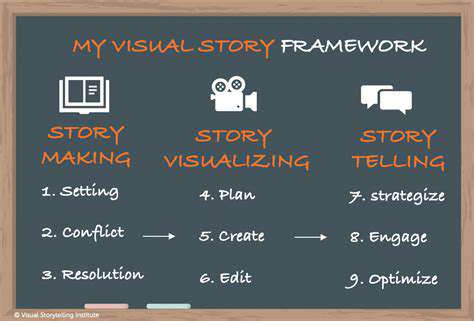

Measuring material circularity is a complex undertaking requiring the development of comprehensive metrics that capture the full lifecycle of materials. These metrics must account for factors such as material extraction, processing, manufacturing, use, and end-of-life management. A key component of such metrics is the quantification of material recovery and reuse rates throughout the entire lifecycle. This allows for a more accurate assessment of the circularity of a specific material or product.

Different metrics exist for evaluating various stages of the material lifecycle. Some examples include material input, output, and reuse rates. These metrics are crucial for identifying areas where improvements are needed to enhance material circularity. Understanding the interplay between these factors is essential for creating effective strategies to reduce waste and maximize resource efficiency.

Data Collection and Analysis

Accurate measurement of material circularity necessitates robust data collection and analysis methodologies. This involves gathering data on material flows from extraction to disposal, including detailed information on material composition, processing methods, and end-of-life treatment options. Data collection needs to be consistent across different sectors and regions to facilitate comparisons and identify trends.

Developing standardized data collection protocols and employing advanced analytical techniques, such as life cycle assessments (LCAs), are crucial for reliable measurements. These approaches allow for a comprehensive understanding of the environmental and economic impacts associated with material flows.

Defining Circular Economy Principles

A critical aspect of measuring material circularity is defining the principles of a circular economy. This involves outlining the key tenets for designing products, manufacturing processes, and business models that minimize waste and maximize resource utilization. These principles should be incorporated into policy frameworks and industrial standards to promote systemic change.

Understanding the principles of circularity, such as design for disassembly, material reuse, and closed-loop systems, is essential for creating impactful strategies. This understanding can guide the development of effective policies and practices to support the transition to a more circular economy.

Lifecycle Assessment (LCA)

Life cycle assessment (LCA) is a valuable tool for evaluating the environmental impacts of materials throughout their entire lifecycle. It considers the environmental burdens associated with raw material extraction, manufacturing, use, and disposal. LCA helps identify the most impactful stages of the material lifecycle and pinpoint areas for improvement.

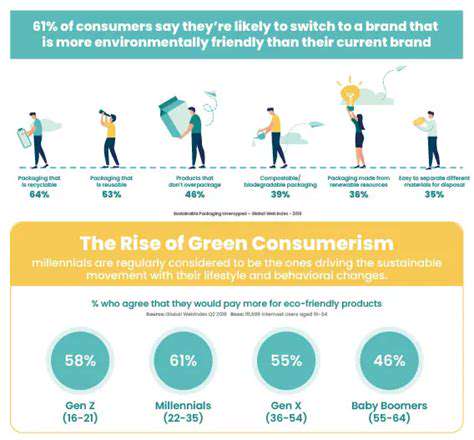

Material Recovery and Recycling Rates

Measuring material recovery and recycling rates provides a direct insight into the effectiveness of circular economy initiatives. These rates indicate the proportion of materials that are recovered and reused or recycled at various stages of the material lifecycle. Tracking these rates over time provides valuable data on the progress of circular economy efforts.

By monitoring these rates, businesses and policymakers can understand the effectiveness of different recycling systems and processes, and identify areas for improvement and innovation.

Economic and Social Impacts

Evaluating the economic and social impacts of material circularity is crucial for comprehensive assessment. This involves considering the potential for job creation, economic growth, and reduced environmental burdens. Analyzing the economic benefits of material reuse and recycling can justify policy support for circular economy principles.

Furthermore, understanding the social impacts of material circularity is important for ensuring equitable access to resources and opportunities. This includes considering the potential for job displacement and ensuring that the transition to a circular economy benefits all stakeholders.