The Benefits of Post Consumer Recycled Content in Apparel: New Data

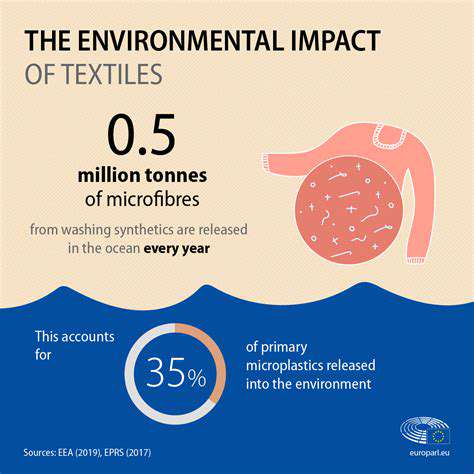

The Environmental Impact of Traditional Textile Production

Water Consumption and Pollution

Traditional textile production, particularly dyeing and finishing processes, often involves substantial water consumption. Large volumes of water are used to process raw materials and to rinse away chemicals and dyes. This high water demand can strain local water resources, particularly in areas with already limited supplies. Furthermore, the discharge of wastewater containing harmful chemicals and dyes can lead to severe water pollution, impacting aquatic ecosystems and human health. This pollution can persist in water bodies for years, harming fish populations and other wildlife.

The dyes and chemicals used in the traditional textile production process can also leach into the environment, contaminating soil and groundwater. This contamination can have long-term effects on the surrounding ecosystems and potentially affect human health through the food chain.

Land Degradation and Deforestation

The cultivation of cotton, a major raw material for traditional textiles, often requires extensive land use. Monoculture farming practices, frequently employed in large-scale cotton production, can lead to soil erosion and nutrient depletion. This degradation of the soil reduces its fertility and productivity over time, impacting agricultural sustainability. Furthermore, the demand for land for cotton cultivation often contributes to deforestation, as forests are cleared to make way for agricultural fields.

The production of synthetic fibers used in traditional textile manufacturing also contributes to land degradation. The extraction of raw materials for synthetic fiber production can involve mining and processing activities that can damage the landscape and pollute surrounding areas.

Air Pollution and Greenhouse Gas Emissions

The energy-intensive processes involved in traditional textile manufacturing, such as dyeing, bleaching, and finishing, release significant amounts of air pollutants. These pollutants, including volatile organic compounds (VOCs) and particulate matter, can contribute to air pollution, leading to respiratory problems and other health issues in nearby communities. The manufacturing processes also often rely on fossil fuels, contributing to greenhouse gas emissions, which exacerbate climate change.

The transportation of raw materials and finished products also contributes to air pollution due to the emissions from vehicles and other transportation means. These emissions contribute to the overall environmental burden of traditional textile production.

Chemical Usage and Hazardous Waste

Traditional textile production heavily relies on various chemicals for dyeing, bleaching, and finishing processes. Many of these chemicals are hazardous and can pose significant risks to human health and the environment. Improper disposal of these chemicals and the resulting hazardous waste can lead to soil and water contamination, threatening ecosystems and human health. The production and use of these chemicals also contribute to the overall environmental footprint.

Impact on Biodiversity and Ecosystem Health

The environmental impacts of traditional textile production extend beyond direct pollution. The conversion of natural habitats to agricultural land for cotton cultivation and the contamination of water bodies negatively affect biodiversity. The disruption of natural ecosystems can lead to a decline in plant and animal populations, disrupting the balance of the ecosystem. The introduction of harmful chemicals and the release of pollutants affect the delicate balance within these ecosystems.

The overall environmental impact of traditional textile production underscores the need for sustainable alternatives, such as post-consumer textile recycling and innovative manufacturing processes, to reduce the detrimental effects on our planet.

The Economic Advantages of Utilizing PCR

Reduced Material Costs

One of the most significant economic advantages of utilizing PCR (Post-Consumer Recycled) materials is the Reduced material costs associated with production. PCR often replaces virgin materials, which typically come with a higher price tag due to the energy and resources required for their extraction and processing. This substitution directly translates to lower input costs for manufacturers, allowing them to pass on savings to consumers in the form of lower prices or increased profitability.

The reduction in material costs is not just limited to the raw material itself. Recycling processes often generate less waste and require fewer energy-intensive steps compared to virgin material production. These efficiencies lead to further cost savings throughout the supply chain, making PCR a more economically viable option for businesses compared to traditional methods.

Increased Supply Chain Resilience

Utilizing PCR enhances supply chain resilience by diversifying material sources. Dependence on a single, potentially volatile, source of virgin materials can leave businesses vulnerable to price fluctuations and supply disruptions. By incorporating PCR into their operations, companies can build a more robust supply chain, less susceptible to external shocks. This is particularly critical in today's dynamic global market.

Diversifying material sources also reduces reliance on specific geographic regions for raw materials, potentially mitigating risks associated with geopolitical instability or natural disasters. A more diversified supply chain is generally more resilient and stable, providing a significant economic advantage in the long run.

Environmental Regulations and Incentives

Many governments are implementing policies and regulations that incentivize the use of recycled materials, often through tax credits, subsidies, or mandatory sourcing requirements. Businesses that utilize PCR can benefit from these incentives, potentially reducing their overall operational costs and gaining a competitive edge in the market.

Beyond direct financial incentives, compliance with environmental regulations related to waste management and resource conservation also contributes to the economic advantages of utilizing PCR. Companies that actively use PCR often demonstrate a commitment to sustainability, which can enhance their brand image and attract environmentally conscious consumers, ultimately boosting profitability.

Furthermore, the increasing demand for sustainable products is driving consumer preference towards PCR materials. Businesses that embrace this trend and incorporate PCR effectively can tap into this growing market segment, securing a competitive advantage and potentially achieving higher profitability.

These environmental regulations and incentives can create a positive feedback loop, encouraging further development and adoption of PCR materials, leading to a more sustainable and economically viable circular economy.