The Human Impact of Fast Fashion: Stories from the Supply Chain

The Globalized Textile Industry

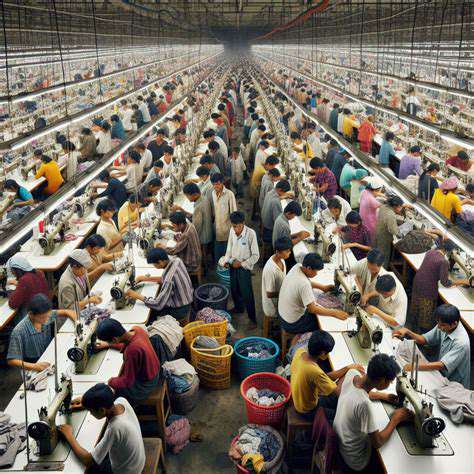

The globalized textile industry, while offering affordable clothing to consumers, often operates under exploitative labor conditions. The demand for cheap clothes fuels a system where workers in developing nations are paid meager wages and subjected to unsafe working environments. This intricate web of production, distribution, and consumption creates a complex challenge in ensuring fair treatment for those involved in the garment industry.

This system extends far beyond the factory floor, encompassing the entire supply chain. From raw material sourcing to final retail sales, numerous players contribute to the production of inexpensive garments, each with a responsibility to uphold ethical standards and consider the impact of their actions on workers.

Unfair Labor Practices

Unfortunately, numerous reports detail unfair labor practices within the garment industry. Workers often face long hours, inadequate safety measures, and a lack of basic protections, including fair wages and safe working conditions. These conditions, perpetuated by the drive for maximum profit margins, directly impact the well-being of those who produce the clothes we wear daily.

Exploitation extends beyond factory work to include issues like forced labor and child labor, which are deeply concerning and violate fundamental human rights. These practices highlight the ethical dilemmas inherent in the pursuit of low-cost clothing.

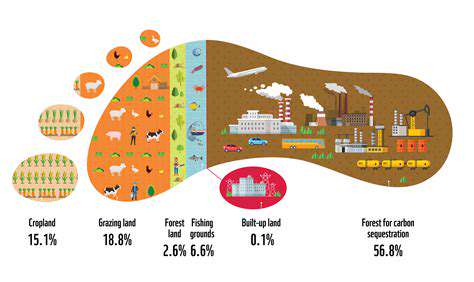

Environmental Impact

The production of cheap clothing also has a significant environmental impact. The use of harmful chemicals in dyeing and manufacturing processes can contaminate water sources and harm ecosystems. The sheer volume of textile waste generated from discarding garments further exacerbates the environmental burden.

Consumer Responsibility

Consumers play a vital role in addressing the issues surrounding cheap clothing. By making conscious purchasing decisions and supporting brands committed to ethical practices, consumers can contribute to positive change. Researching the origin of clothing, considering the environmental impact, and understanding worker rights are crucial steps to becoming more informed and responsible shoppers.

Supporting fair trade and sustainable brands, as well as advocating for better working conditions and environmental regulations, empowers consumers to drive positive change within the industry.

The Role of Brands and Retailers

Brands and retailers have a significant responsibility to ensure ethical and sustainable practices throughout their supply chains. Implementing fair labor standards, promoting safe working environments, and using sustainable materials are crucial steps in minimizing the negative impacts of their operations.

The Cost of Ignoring Ethical Concerns

Ultimately, ignoring the ethical and environmental concerns surrounding cheap clothing comes at a significant cost. This cost extends far beyond financial implications, encompassing social, environmental, and human rights violations. Addressing these issues is not merely a matter of corporate social responsibility; it is a fundamental human right. Prioritizing ethical production and consumption patterns is essential for a more sustainable and equitable future.

The Long Shadow of Production: Child Labor and Forced Labor

The Global Scope of the Problem

Child labor and forced labor are pervasive issues affecting children and adults across the globe, from the bustling factories of developing nations to the hidden sweatshops of industrialized countries. This exploitation, often masked by complex supply chains and obscured by geographical distance, touches virtually every sector of production, from agriculture and manufacturing to mining and domestic service. The consequences for these individuals are devastating, impacting their physical and mental well-being, and condemning them to a life of hardship and inequality.

The scale of this problem is staggering, representing a profound violation of human rights and a significant impediment to global development. The lack of transparent and accountable systems often enables this exploitation to persist, hiding the true cost of products behind a veil of economic activity.

Economic Factors Driving Exploitation

Poverty, a lack of accessible education, and the allure of immediate income are often the primary drivers behind the use of child labor and forced labor. Families facing economic hardship may see children as a source of income, while employers may find it more cost-effective to exploit vulnerable individuals than to invest in fair wages and safe working conditions. The relentless pursuit of profit, especially in industries with low regulations, can create a fertile ground for this type of exploitation.

Global economic pressures, including competition and demand for cheap goods, can contribute to the perpetuation of these practices. While consumer demand is not the direct cause, the desire for affordable products can inadvertently incentivize exploitative labor practices in the production process. This complex interplay of economic forces and human rights violations requires a multifaceted approach to address the root causes.

The Human Cost: Physical and Psychological Trauma

The physical and psychological toll of child labor and forced labor is immeasurable. Children are often subjected to dangerous working conditions, leading to physical injuries, illnesses, and premature death. These experiences can leave lasting scars, affecting their physical health, cognitive development, and overall well-being, often leading to long-term disabilities and chronic health problems.

Beyond the physical harm, the psychological trauma is equally devastating. Children and adults subjected to forced labor often experience profound emotional distress, including anxiety, depression, and post-traumatic stress disorder. The violation of their basic human rights, the loss of their childhood, and the constant threat of abuse can have a profound impact on their mental and emotional well-being. The damage inflicted often goes far beyond the immediate circumstances of labor.

Ethical Considerations and Corporate Responsibility

The issue of child labor and forced labor raises significant ethical considerations for businesses and consumers. Companies have a responsibility to ensure that their supply chains are free from exploitation. Implementing ethical sourcing practices, conducting thorough audits, and engaging in transparent communication with suppliers are crucial steps in combating this issue.

Consumers also play a vital role. By supporting companies committed to ethical sourcing and avoiding products associated with exploitative labor practices, they can contribute to a more just and equitable global economy. Choosing ethical alternatives, even if they are slightly more expensive, is an important step in supporting a future free from the shadows of production exploitation.

Legal Frameworks and Enforcement Strategies

International conventions and national laws aim to protect children and workers from exploitation. The United Nations Convention on the Rights of the Child, along with various labor laws, outline the rights of children and workers, prohibiting child labor and forced labor. However, enforcement mechanisms often face significant challenges in ensuring compliance, particularly in regions where regulatory oversight is weak or corruption is prevalent.

Strengthening legal frameworks, increasing resources for labor inspectors, and promoting international cooperation are essential to combatting this global issue effectively. Addressing the systemic issues that enable exploitation requires a coordinated effort from governments, businesses, and civil society organizations to create lasting change.

From Factory to Landfill: Environmental Consequences

Environmental Impact of Manufacturing

Manufacturing processes, while vital for economic growth, often have significant environmental consequences. The sheer volume of materials used, the energy consumed, and the waste generated contribute to pollution and resource depletion. This impact extends beyond the factory gates, affecting air and water quality, and contributing to greenhouse gas emissions, which, in turn, exacerbate climate change. Understanding these impacts is crucial for developing sustainable manufacturing practices.

Raw material extraction often involves deforestation, habitat destruction, and soil erosion. These actions disrupt ecosystems and biodiversity, leading to long-term environmental damage. Furthermore, transporting these raw materials across vast distances adds to the overall carbon footprint of the manufacturing process. Reducing the environmental impact of manufacturing requires careful consideration of every stage of the process, from sourcing raw materials to disposing of finished products.

Waste Management Challenges

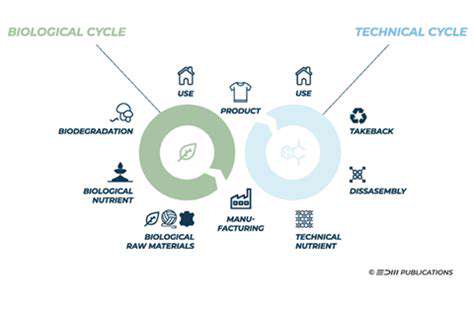

The production of goods inevitably generates waste, from packaging materials to manufacturing byproducts. Often, this waste ends up in landfills, contributing to soil and water contamination. Proper waste management is essential for minimizing the environmental damage caused by these byproducts. Effective recycling and reuse programs are crucial for diverting waste from landfills and promoting circular economy principles. Developing sustainable waste management strategies is critical for mitigating the environmental impact of manufacturing.

Landfills often pose significant environmental hazards due to leachate contamination, which can seep into groundwater sources. This contamination can have severe consequences for human health and the surrounding ecosystem. Minimizing waste generation and implementing effective recycling and reuse strategies are vital steps towards reducing the burden on landfills and protecting our environment.

Sustainable Material Sourcing

The materials used in manufacturing significantly affect the environmental footprint of a product. Choosing sustainable materials, such as recycled content or bio-based materials, can drastically reduce the environmental impact of the manufacturing process. Sustainable sourcing practices ensure that materials are obtained without jeopardizing ecosystems or depleting resources. These practices also support responsible forestry and mining operations.

Prioritizing the use of renewable materials and recycled content minimizes the demand for virgin resources, thereby reducing the environmental strain associated with resource extraction. This approach also supports the development of a more circular economy, where materials are reused and recycled, minimizing waste and maximizing resource efficiency.

Energy Consumption and Efficiency

Manufacturing processes often require substantial amounts of energy. Reducing energy consumption is a key aspect of minimizing the environmental impact of manufacturing. Implementing energy-efficient technologies and processes can lead to significant reductions in greenhouse gas emissions. Investing in renewable energy sources for manufacturing operations further enhances sustainability.

Energy efficiency initiatives can encompass various strategies, including improving machinery efficiency, optimizing production processes, and implementing smart energy management systems. Transitioning to renewable energy sources for powering manufacturing facilities is also crucial for achieving a low-carbon footprint.

Product Design for Environmental Impact

Product design plays a critical role in determining the environmental impact of a product throughout its lifecycle. Designing products with durability, repairability, and recyclability in mind can significantly reduce waste and emissions. Lightweight materials and efficient designs can reduce the overall resource consumption required for manufacturing. These features contribute to a more sustainable product lifecycle.

Product design for disassembly and recycling is essential for facilitating the circular economy. Designing products that can be easily taken apart and their components recycled reduces the environmental burden associated with end-of-life disposal. This approach minimizes landfill waste and promotes the reuse of valuable materials.

The Role of Policy and Regulation

Effective environmental policies and regulations are essential for driving sustainable manufacturing practices. Government regulations and incentives can encourage businesses to adopt environmentally friendly technologies and processes. These policies can mandate the use of sustainable materials, establish stricter emission standards, and encourage the development of circular economy models. Stricter regulations can effectively curb harmful emissions and resource depletion.

Policy interventions can include carbon taxes, subsidies for renewable energy, and mandatory recycling requirements. These measures encourage businesses to internalize environmental costs, making sustainability a more profitable proposition. Robust environmental regulations are crucial for achieving significant improvements in the environmental performance of the manufacturing sector.