Sustainable Fashion Trends: What to Expect in the Coming Years

Designing for Durability and Longevity

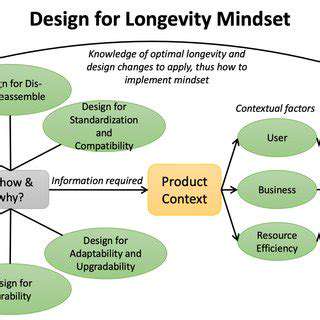

At the heart of circular economy principles lies the concept of designing products to last. Manufacturers who focus on creating durable goods with high-quality materials inherently reduce the frequency of replacements needed by consumers. This strategy not only conserves resources but also aligns with growing consumer demand for sustainable products. When items are built to withstand the test of time, they require fewer raw materials over their extended lifespan.

An often overlooked aspect of product design is planning for future maintenance. Products designed with modular components and standardized parts make repairs significantly easier, encouraging users to fix rather than discard. This philosophy challenges the disposable culture that has dominated manufacturing for decades, paving the way for a more responsible approach to consumption.

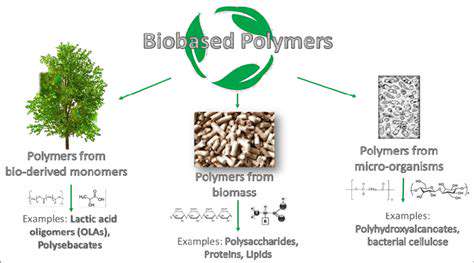

Utilizing Renewable and Recycled Materials

The transition to circular manufacturing requires a fundamental shift in material sourcing. Instead of relying solely on virgin resources, progressive companies are discovering innovative ways to incorporate recycled content into their products. This practice dramatically reduces the environmental toll of mining and extraction while keeping valuable materials in circulation.

Advanced material science now allows for the creation of high-performance products using post-consumer waste. From plastic bottles transformed into durable fabrics to reclaimed wood finding new life as furniture, these applications demonstrate how waste streams can become valuable resources. This closed-loop approach represents a significant step toward reducing industrial waste and conserving natural resources.

Promoting Product Sharing and Reuse

Modern consumption patterns are undergoing a radical transformation as sharing economies gain traction. The concept of product-as-service models challenges traditional ownership paradigms, offering consumers access to goods without the burden of permanent possession. Car-sharing platforms, tool libraries, and clothing rental services exemplify how shared usage can optimize resource efficiency.

Enhancing Product Repairability and Remanufacturing

The right-to-repair movement has gained momentum as consumers demand products designed for longevity. Manufacturers responding to this trend are creating devices with standardized components and providing detailed repair documentation, empowering users to extend product lifespans. This shift represents a fundamental change from the planned obsolescence that characterized previous manufacturing eras.

Remanufacturing processes breathe new life into used products, restoring them to like-new condition at a fraction of the environmental cost of new production. Industrial equipment, electronics, and automotive parts particularly benefit from this approach, which preserves the embedded energy and materials from the original manufacturing process.

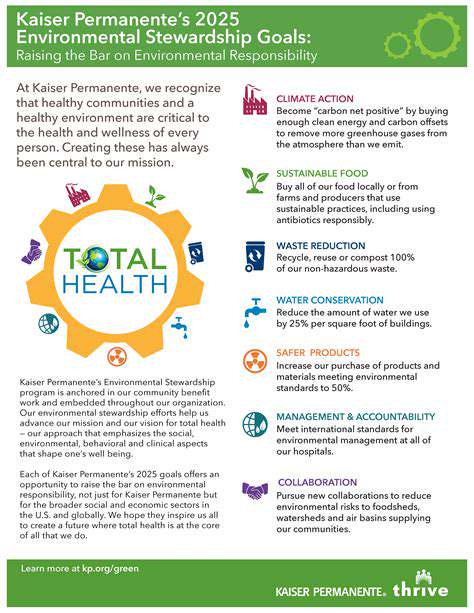

Developing Closed-Loop Systems

True circularity requires systemic thinking that encompasses the entire product lifecycle. Forward-thinking companies are implementing take-back programs and material recovery systems that ensure products don't end up in landfills. These comprehensive approaches consider every stage from material sourcing to end-of-life recovery, creating economic value while minimizing environmental impact.

The most advanced closed-loop systems incorporate digital tracking technologies to monitor material flows throughout the supply chain. This transparency enables companies to optimize resource recovery and identify opportunities for continuous improvement in their circular practices.

Upcycling and Repurposing: Giving Old Threads New Life

Innovative Ways to Upcycle Clothing

The art of upcycling transforms worn garments into creative new items, merging sustainability with personal expression. Skilled artisans and DIY enthusiasts alike are discovering that with basic sewing skills and imagination, outdated clothing can become contemporary fashion statements. A dress shirt might become a stylish apron, while damaged denim can transform into fashionable accessories.

The Environmental Benefits of Repurposing

Textile waste represents one of the fastest-growing waste streams globally, making clothing repurposing an essential sustainability practice. Every upcycled garment prevents approximately 7.5 pounds of carbon emissions that would result from manufacturing new clothing. This practice also conserves the thousands of gallons of water typically required to produce new textiles, addressing two critical environmental challenges simultaneously.

Repurposing for Budget-Conscious Fashion

In an era of economic uncertainty, upcycling offers both financial and environmental benefits. Transforming existing garments eliminates the need for new purchases while allowing for personal style expression. Thrifted items provide affordable raw materials for creative projects, making high-fashion looks accessible without the premium price tag.

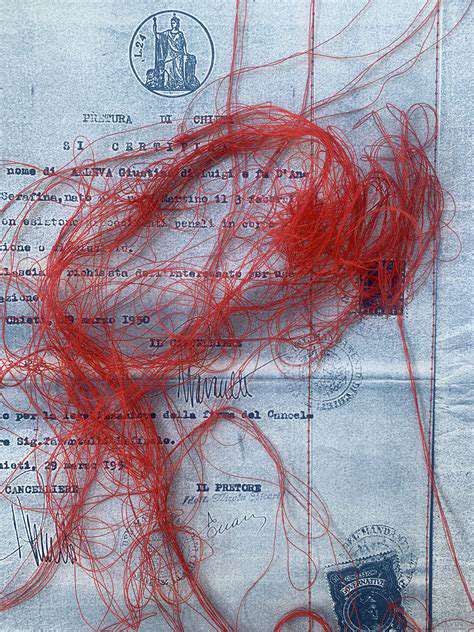

Creative Techniques for Transforming Old Clothes

The spectrum of upcycling techniques ranges from simple alterations to complex reconstructions. Basic methods include tie-dye, distressing, and embroidery, while more advanced projects might involve complete garment reconstruction. Digital platforms have democratized access to these skills, with countless tutorials available for all skill levels.

Finding Inspiration and Resources for Upcycling

Creative communities both online and offline serve as valuable resources for aspiring upcyclers. Local workshops, maker spaces, and online forums provide platforms for sharing techniques and inspiration. Museums and historical costume collections often reveal ingenious historical upcycling methods that can inform contemporary practice.