The Future of Textile Waste Management: Towards a Circular System

Eco-Friendly Dyeing Methods

The fashion industry's coloring processes desperately need transformation. Conventional dye operations dump approximately 200,000 tons of toxic chemicals into waterways annually, according to the World Bank. Fortunately, forward-thinking companies are rediscovering ancient plant-based dyes like indigo and madder root, which produce vibrant hues without synthetic additives. Circular fashion pioneers are proving these natural alternatives can achieve commercial viability when combined with modern color-fixation techniques.

Breakthroughs in microbial dyes - where bacteria produce pigments during fermentation - represent another exciting frontier. These living color systems eliminate wastewater entirely while creating self-replenishing dye stocks. The key challenge remains scaling these solutions to meet industrial demands without compromising their environmental benefits.

Next-Generation Fabric Production

Manufacturing innovations are reshaping what's possible with textiles. Automated cutting systems now achieve 98% material utilization rates, compared to 70-80% with manual methods. Digital knitting machines can produce entire garments with zero seams, reducing both waste and labor costs. Perhaps most remarkably, 3D fabric printing allows designers to grow clothing layer by layer, using precisely the amount of material needed.

These technologies aren't just reducing waste - they're enabling performance breakthroughs. Aerospace companies now use 3D-woven composites that are lighter yet stronger than traditional materials. Medical researchers are developing textiles with built-in antimicrobial properties during the manufacturing process itself.

The Smart Fabric Revolution

Imagine workout clothes that analyze your muscle activity or hospital gowns monitoring vital signs. These aren't futuristic concepts - they're current applications of intelligent textiles. The global smart fabrics market is projected to reach $5.5 billion by 2026 as these technologies mature.

The real game-changer comes when these textiles connect to the Internet of Things. A firefighter's uniform could detect dangerous chemical exposures, while an elderly person's pajamas might alert caregivers to potential falls. These innovations require careful consideration of data privacy and cybersecurity, but the potential benefits are enormous.

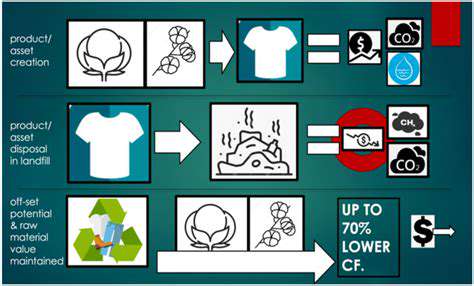

Breathing New Life Into Old Materials

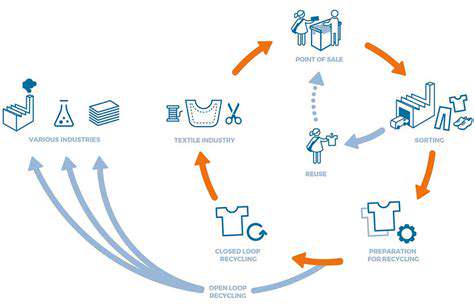

Every second, a garbage truck's worth of textiles gets landfilled or burned. Creative reuse solutions are challenging this waste. Some innovators shred discarded jeans into insulation material, while others unravel sweaters to harvest reusable yarn. The most exciting developments involve chemical recycling that breaks fabrics down to their molecular components for remanufacturing.

Major brands are taking notice. Several outdoor apparel companies now make jackets from recycled ocean plastics, while high-fashion houses incorporate vintage fabrics into new collections. These approaches demonstrate that sustainability and style aren't mutually exclusive.

Nature's Textile Solutions

Researchers are looking to the natural world for fiber inspiration. Mushroom leather, pineapple leaf fiber, and algae-based textiles all show promise as petroleum alternatives. What makes these materials particularly exciting is their built-in sustainability - they're biodegradable and often require less water to produce than conventional fabrics.

The challenge lies in matching the performance expectations consumers have from synthetic materials. Recent advances in bioengineering are helping - some lab-grown silks now rival the strength of Kevlar, while certain plant-based fibers offer natural moisture-wicking properties.

Building Responsible Supply Networks

True sustainability extends beyond materials to encompass how they're sourced and distributed. Leading companies are implementing blockchain systems to track materials from origin to store shelf. This transparency helps ensure ethical labor practices and verifies environmental claims.

The most progressive brands are rethinking distribution models entirely. Some now operate repair and resale platforms, while others offer rental services for special occasion wear. These approaches reduce overall production demands while keeping clothing in use longer.

Collective Action for Industry Transformation

Power of Partnership

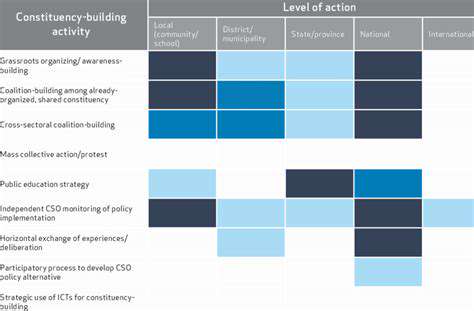

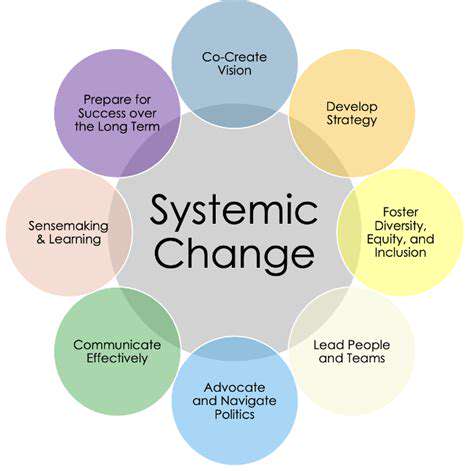

No single company can solve textile waste alone. Successful initiatives often involve unlikely alliances - fast fashion brands teaming with environmental NGOs, or chemical companies collaborating with artisan cooperatives. The common thread is recognizing that each stakeholder brings unique value to the solution.

One promising model involves pre-competitive collaboration, where rivals share research on sustainable materials while competing on product design. Another approach creates regional ecosystems where waste from one facility becomes raw materials for another.

Policy as a Catalyst

Forward-thinking regulations are accelerating change. France's anti-waste law bans destruction of unsold goods, while the EU's textile strategy sets binding eco-design requirements. These policies work best when they provide clear targets while allowing flexibility in how companies achieve them.

Emerging extended producer responsibility (EPR) schemes make brands financially accountable for product end-of-life. This creates powerful incentives to design for durability and recyclability from the outset.

Communication That Creates Change

Effective sustainability initiatives require breaking down silos between departments. Regular cross-functional meetings help align R&D, design, and marketing teams around common goals. Some companies appoint sustainability translators who can bridge technical and business perspectives.

The most impactful communications often come from unexpected sources. When factory workers share waste reduction ideas, or when marketing teams reframe sustainability as desirability, real transformation begins.

Transparency as Standard Practice

Radical transparency is becoming the new normal. Progressive brands now publish detailed impact reports, including shortcomings. This honesty builds trust and drives continuous improvement.

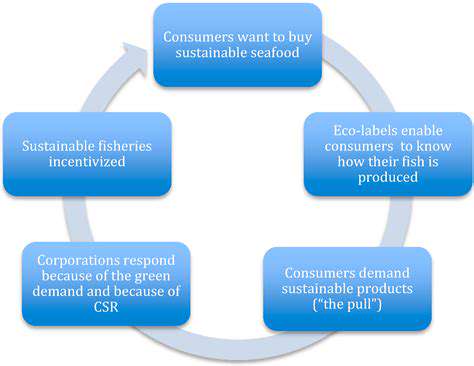

Digital product passports - QR codes revealing a garment's full lifecycle impacts - empower consumers to make informed choices. When combined with take-back programs, these tools help close the loop on textile waste.