The Power of Collaboration in Driving Systemic Change in Fashion

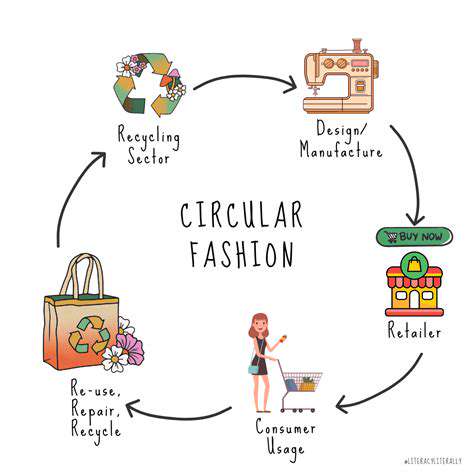

Cultivating a Culture of Circularity

Designing for Disassembly

One of the most transformative strategies in sustainable manufacturing involves creating products that can be easily taken apart at the end of their useful life. Forward-thinking companies now recognize that true sustainability requires planning for a product's entire journey, from conception to eventual recycling. When manufacturers implement modular designs with standardized connectors and minimal adhesives, they create opportunities for efficient material recovery.

This philosophy transforms waste management by enabling components to find new purposes rather than ending up in landfills. Businesses that adopt this approach often discover unexpected benefits, including cost savings from recovered materials and enhanced brand loyalty from environmentally conscious consumers.

Material Selection and Sourcing

The foundation of any sustainable product lies in its material composition. Progressive organizations are shifting toward materials with verified recycled content and renewable origins, while simultaneously examining the complete environmental footprint of their supply chains. This comprehensive evaluation includes considering water usage, energy consumption, and transportation impacts at every production stage.

Industry leaders are establishing partnerships with suppliers who demonstrate transparent, ethical practices, from responsibly managed forests to mines implementing cutting-edge reclamation techniques. These collaborations frequently yield innovative material solutions that benefit both business operations and ecological systems.

Promoting Product Durability and Longevity

In an era of disposable consumer goods, designing products to withstand years of use represents a radical departure from conventional practices. Manufacturers committed to sustainability invest in superior materials and engineering solutions that maintain functionality through extended use cycles. This commitment often involves rigorous testing protocols and quality control measures that exceed industry standards.

Forward-looking companies complement durable designs with comprehensive maintenance programs, offering everything from repair guides to authorized service networks. These initiatives not only extend product life but also foster deeper customer relationships through ongoing engagement.

Facilitating Product Sharing and Reuse

The sharing economy has introduced revolutionary alternatives to traditional ownership models. Innovative platforms now enable temporary access to everything from power tools to high-end fashion, dramatically reducing the resources required to meet consumer needs. These systems often incorporate smart technologies for inventory management and user verification, creating efficient utilization of existing assets.

Beyond equipment sharing, visionary businesses are developing take-back programs that refurbish and recirculate used products. Some industries now treat products as services, maintaining ownership while providing access, which aligns economic incentives with sustainable outcomes.

Implementing Effective Recycling and Recovery Systems

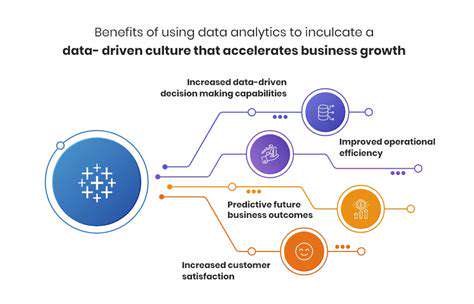

Closing the materials loop requires sophisticated infrastructure capable of processing diverse waste streams. Modern recycling facilities now employ advanced sorting technologies, from AI-powered optical scanners to specialized chemical processes that separate complex material composites. The most successful programs combine technological solutions with behavioral nudges that encourage proper consumer participation.

Pioneering organizations are experimenting with innovative approaches like deposit return schemes and material passports that track composition throughout a product's life. These systems create economic value from waste while providing crucial data for continuous improvement of material choices.

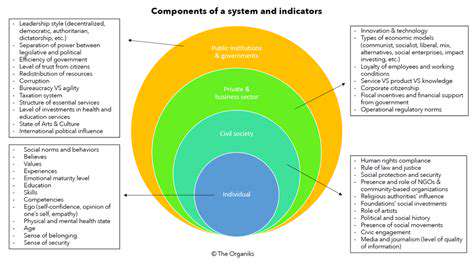

Encouraging Innovation and Collaboration

The transition to circular systems demands unprecedented cooperation across traditional boundaries. Breakthroughs often emerge when manufacturers partner with academic institutions, startups, and even competitors to solve complex material challenges. These alliances frequently result in patent-sharing agreements and open-source solutions that accelerate industry-wide progress.

Government agencies play a crucial role by establishing supportive policy frameworks and funding pilot projects. Meanwhile, consumer education initiatives help bridge the gap between technical solutions and real-world adoption, creating a virtuous cycle of innovation and implementation.