Building Resilient and Ethical Supply Chains: New Models

Beyond the Numbers: Strategic Alignment

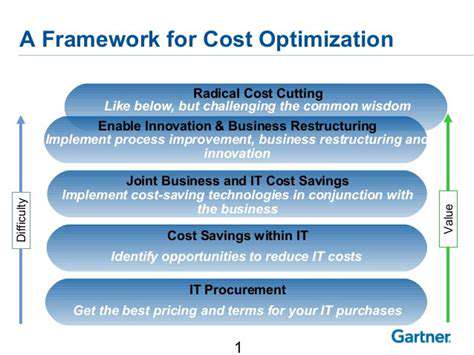

Cost optimization, while crucial, often overlooks the broader strategic implications of integration. A successful integration isn't just about reducing expenses; it's about aligning disparate teams and processes to achieve a unified vision. This involves understanding the strategic goals of the combined entity and ensuring that all departments and initiatives contribute towards those goals. Failing to align integration efforts with overarching strategy can lead to wasted resources and diminished returns. Ultimately, the focus should be on creating a synergistic effect, where the sum is greater than the parts.

Identifying and addressing potential conflicts in workflows and communication channels early on is key to a smooth transition. By fostering collaboration and understanding between formerly separate teams, the organization can build a stronger foundation for long-term success. This often necessitates training programs and communication strategies to bridge cultural gaps and ensure everyone is working towards a common objective. Clear, concise communication about expectations and objectives is absolutely critical.

People and Culture: The Human Element

Integration is not solely about technology and processes. The human element is often overlooked, but it is arguably the most critical aspect of a successful integration. Changing organizational structures and responsibilities can cause significant stress and uncertainty among employees. Addressing these concerns proactively through open communication and support systems is essential.

Recognizing and addressing individual concerns, providing opportunities for professional development, and fostering a welcoming and inclusive environment are all vital components of successful employee integration. Investing in employee well-being during this transition period can significantly reduce potential resistance and foster a more positive and productive work environment. This includes clear communication about the reasons for the integration, the expected changes, and the support systems available to employees.

Process Re-engineering and Technological Integration

Effective integration demands a comprehensive review and re-engineering of existing processes. This is not simply about streamlining existing procedures but about identifying redundancies, inefficiencies, and opportunities for improvement. Analyzing workflows, evaluating current technological capabilities, and identifying areas for process optimization are crucial steps in this process. This may include adopting new software or tools to enhance collaboration and improve efficiency.

Furthermore, a thorough assessment of the technology landscape is essential to ensure seamless integration. This could involve migrating data, consolidating systems, or implementing new technologies to support the combined entity's needs. Addressing potential compatibility issues and ensuring data security protocols are robust and compliant are critical aspects of this stage. Poorly managed technological integration can lead to significant downtime, security risks, and operational disruptions. Careful planning and execution are vital to avoid these pitfalls.

Promoting Collaboration and Transparency Throughout the Chain

Fostering Open Communication

Effective collaboration hinges on transparent communication throughout the supply chain. This means establishing clear channels for information sharing, enabling real-time updates on production progress, delivery timelines, and potential disruptions. Open communication fosters trust and allows all stakeholders to be aware of the current status and potential challenges, enabling proactive problem-solving and minimizing risks. Transparent communication also builds a culture of accountability, where everyone understands their role and responsibilities within the supply chain.

Promoting regular meetings, utilizing collaborative platforms, and implementing a standardized communication protocol are crucial steps to achieve this. This proactive approach ensures everyone is informed and can address any issues quickly, ultimately strengthening the resilience of the entire chain.

Building Trust Among Stakeholders

Trust is the cornerstone of any successful collaborative effort. Building trust within the supply chain involves fostering relationships based on mutual respect, reliability, and a commitment to shared goals. This involves actively engaging with partners, understanding their needs, and demonstrating a willingness to work together to overcome challenges. Transparency, as previously mentioned, plays a significant role in building trust, as it allows stakeholders to see the integrity and commitment of their partners.

Regular feedback mechanisms and opportunities for open dialogue create a platform for addressing concerns and conflicts promptly. This fosters a sense of shared responsibility and commitment, allowing the chain to adapt and overcome obstacles more effectively.

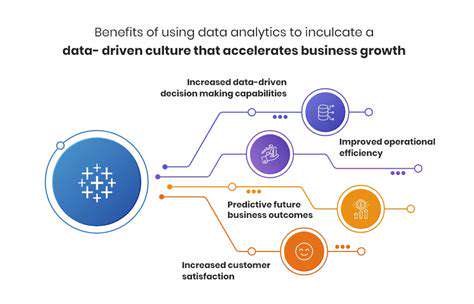

Implementing Collaborative Technologies

Modern technologies offer powerful tools for enhancing collaboration and transparency throughout the supply chain. These include cloud-based platforms for data sharing, real-time tracking systems for inventory and shipments, and project management tools that allow stakeholders to monitor progress and communicate efficiently. Utilizing these technologies can significantly streamline operations, improve visibility, and reduce delays.

Implementing these technologies requires careful planning and integration with existing systems, but the benefits in terms of efficiency, responsiveness, and risk mitigation are substantial. This integration also creates a more unified and resilient supply chain.

Encouraging Cross-Functional Collaboration

Breaking down departmental silos and promoting cross-functional collaboration is essential for a resilient supply chain. This involves encouraging communication and knowledge sharing between departments like procurement, logistics, production, and sales. By fostering a collaborative environment where different teams work together towards common objectives, the chain can become more flexible and responsive to changing market conditions.

This inter-departmental collaboration allows for a more comprehensive understanding of the entire supply chain process, leading to better decision-making and problem-solving. This can also lead to increased innovation and efficiency as diverse perspectives are considered.

Establishing Clear Roles and Responsibilities

Defining clear roles and responsibilities for each stakeholder within the supply chain is crucial for ensuring accountability and efficiency. This involves outlining the specific tasks, expectations, and decision-making authority for each party. Having a well-defined structure allows for a smooth flow of information and reduces ambiguity.

Clear roles and responsibilities also enhance communication and coordination by establishing protocols for reporting, feedback, and problem-solving. This structure provides a solid foundation for transparency and promotes the efficient execution of supply chain activities.

Promoting Continuous Improvement

A resilient supply chain is not static; it requires continuous improvement and adaptation. This involves establishing mechanisms for feedback collection, performance monitoring, and process optimization. Regular reviews and analysis of supply chain performance can identify areas for improvement and highlight potential risks. This proactive approach allows for the identification of bottlenecks, inefficiencies, and vulnerabilities, which can then be addressed through targeted interventions.

The implementation of a culture of continuous improvement fosters a proactive and adaptive approach to supply chain management. This ensures the chain is always evolving to meet changing market demands and emerging challenges.