The Global Impact of Textile Recycling

The Unseen Impact of Fast Fashion

Fast fashion's relentless cycle of rapid design changes and low-cost production has birthed a silent environmental catastrophe. While shoppers enjoy affordable, trendy apparel, few grasp the staggering ecological toll behind each purchase. The industry's dependence on exploitative labor and resource-intensive methods generates mountains of discarded fabrics, poisoning waterways and overflowing landfills worldwide.

This throwaway culture fuels an alarming global spike in textile waste. Landfills now bulge with cast-off garments that release toxic chemicals as they decompose over decades. Beyond waste, the manufacturing process itself guzzles water and spews pollution, leaving permanent scars on ecosystems.

The Environmental Toll of Textile Waste

Textile production's environmental devastation extends far beyond factory walls. The dyeing process alone contaminates millions of gallons of freshwater daily with hazardous chemicals that decimate aquatic life and threaten human health downstream.

As synthetic fibers break down in landfills, they emit methane - a greenhouse gas 25 times more potent than carbon dioxide. Meanwhile, producing virgin textiles demands ever-increasing amounts of petroleum, water, and arable land, pushing planetary boundaries to their limits.

The Social Costs of Unsustainable Practices

Behind every bargain-priced garment lies a hidden human cost. Workers in developing nations face dangerous conditions, poverty wages, and systemic abuse to meet Western demand for cheap clothing. This exploitation remains conveniently invisible to consumers mesmerized by ever-changing racks of discounted apparel.

The fallout extends beyond factory walls, destabilizing entire communities dependent on volatile fashion cycles. Without radical change, these social inequities will only deepen as fast fashion accelerates.

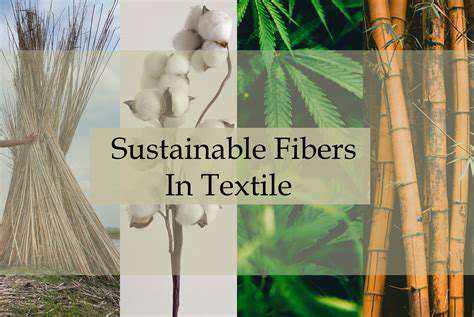

The Need for Sustainable Alternatives

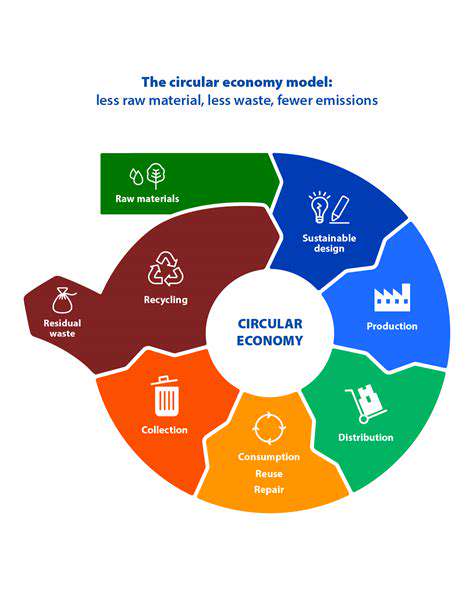

Transforming this broken system requires reinventing textiles from fiber to finish. Breakthrough innovations - from mushroom leather to algae-based dyes - offer genuine hope for reducing fashion's footprint. Circular business models that design waste out of the equation could finally break the take-make-waste cycle that dominates the industry.

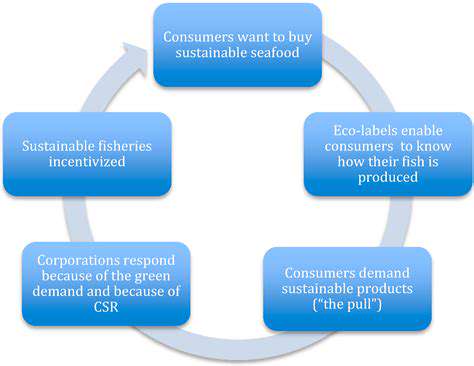

Consumer Responsibility in Reducing Textile Waste

Shoppers hold surprising power to drive change through their wallets. Choosing timeless pieces over fleeting trends, repairing beloved items, and buying secondhand all starve the fast fashion beast. When consumers collectively shift toward quality and longevity, corporations must follow or perish.

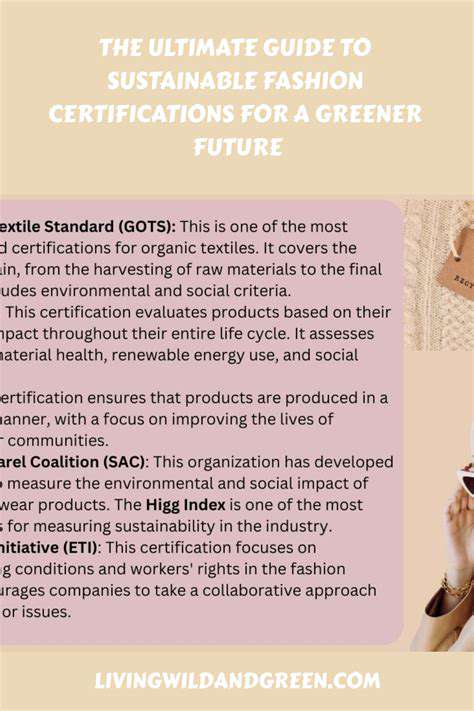

Policy Interventions and Industry Regulation

Governments must stop treating fashion like a frivolous industry and start regulating it like the environmental emergency it's become. Binding extended producer responsibility laws could force brands to fund recycling infrastructure and clean up their pollution. Until policymakers hold corporations accountable, voluntary sustainability pledges will remain empty PR stunts.

The Economic Advantages of Textile Recycling: A Circular Economy Approach

Raw Material Availability and Cost

Traditional textile production teeters on volatile global commodity markets, but recycled materials offer price stability. Discarded clothing represents an untapped goldmine - over 100 billion garments are produced annually, with most ending up in landfills. Smart companies are realizing old clothes could become their cheapest and most sustainable raw material.

Manufacturing Efficiency and Technology

Cutting-edge fiber-to-fiber recycling technologies are turning yesterday's t-shirts into tomorrow's haute couture without quality loss. These breakthroughs slash water and energy use while creating closed-loop systems where waste becomes feedstock rather than landfill fodder.

Labor Costs and Availability

While recycling facilities require skilled technicians, they offer safer, higher-paying jobs than conventional garment factories. This workforce development opportunity could revitalize post-industrial communities decimated by offshoring.

Scale of Operations and Economies of Scale

Pioneering brands are proving circular models can achieve profitability at scale. As recycling infrastructure expands, per-unit costs will plummet - making sustainable textiles cheaper than virgin materials.

Market Access and Distribution

Consumers increasingly reward brands with authentic sustainability credentials. Companies that transparently track recycled content gain premium positioning and customer loyalty in crowded markets.

Environmental Sustainability and Ethical Practices

The next generation of shoppers votes with their wallets, favoring brands that align with their values. Forward-thinking companies recognize sustainability isn't just ethics - it's becoming the only viable business model.

Technological Advancements Driving Textile Recycling Efficiency

The Rise of AI-Powered Tools

AI-driven optical sorting systems can now identify fiber compositions with 95% accuracy, revolutionizing textile waste processing. These smart systems learn continuously, improving their ability to separate complex fabric blends that previously doomed recycling efforts.

Enhanced Communication and Collaboration

Blockchain-enabled supply chains create unprecedented transparency, allowing consumers to verify recycled content claims while helping manufacturers optimize material flows.

Improved Data Management and Analysis

Advanced analytics help recyclers predict fashion waste streams months in advance, allowing smarter capacity planning and inventory management.

Automation of Repetitive Tasks

Robotic disassembly systems can now process mixed textile waste 50 times faster than human workers, making large-scale recycling economically viable for the first time.

The Internet of Things (IoT) Revolution

Smart bins with RFID tracking help municipalities capture more textile waste while providing data to optimize collection routes and recycling facility inputs.

Advancements in Cloud Computing

Cloud-based material marketplaces connect global suppliers of post-consumer textiles with manufacturers, creating efficient new secondary raw material markets.