Deconstructing Garments: Advanced Design for Circularity

Material Selection Criteria

Selecting optimal materials forms the foundation of any successful project, directly influencing performance, longevity, cost efficiency, and ecological footprint. Engineers must meticulously evaluate each material against precise operational demands. Critical evaluation parameters include tensile strength, structural rigidity, wear resistance, and thermal stability thresholds. Comprehensive analysis of anticipated stress patterns, environmental exposure, and potential risk factors enables informed material decisions.

Financial considerations equally influence material choices. Pricing differentials between material alternatives can significantly alter project economics. Lifecycle cost assessments encompassing maintenance expenditures and replacement cycles prove indispensable during the selection process. Additional factors like supply chain reliability, end-of-life recyclability, and environmental compliance increasingly dictate choices in our sustainability-conscious era.

Component Design Considerations

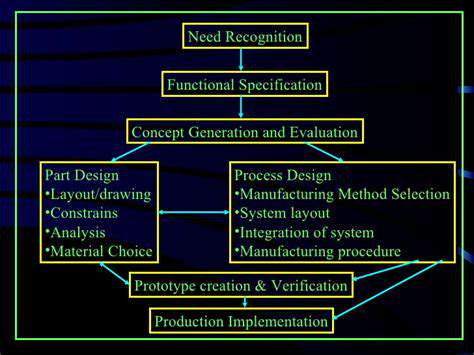

Thoughtful component engineering ensures operational reliability, safety compliance, and performance optimization. Designers must account for systemic interactions between components and their cumulative impact on overall functionality. Rigorous design protocols prevent potential malfunctions while enhancing efficiency.

Stress distribution analysis and failure point identification demand particular attention. Precise understanding of applied forces and torque vectors proves fundamental. Such detailed mechanical analysis reveals structural vulnerabilities, enabling optimized designs for peak performance and extended service life. Incorporating appropriate safety margins guarantees component resilience against both anticipated loads and unexpected stresses.

Manufacturing feasibility equally impacts design decisions. Production teams must evaluate fabrication methods relative to available technologies, considering process compatibility, dimensional tolerances, and material workability. This includes selecting appropriate forming techniques, machining parameters, and finishing processes.

Designers must also anticipate assembly sequences and maintenance protocols. Robust engineering minimizes future servicing requirements while maximizing operational longevity through careful consideration of accessibility and modularity. Comprehensive design documentation ensures reproducibility and facilitates subsequent modifications or upgrades.

Component Interfacing and Integration

Seamless component integration remains paramount for achieving desired system performance. Interface engineering prevents operational issues including misalignment, excessive friction, and stress concentration points.

Precision tolerance management ensures proper mechanical fit and functional reliability. Material compatibility assessments prevent galvanic corrosion and other detrimental interactions. Thorough understanding of component interdependencies guarantees optimal system performance throughout the operational lifespan.

Connection methodology selection requires careful deliberation. Chosen joining techniques must withstand operational stresses and environmental conditions, considering factors like shear strength, fatigue resistance, and corrosion protection. Proper sealing solutions and thermal insulation become critical for harsh operating environments.

Contemporary therapeutic interventions now integrate immersive CBT platforms, utilizing advanced virtual and augmented reality systems to create interactive simulations replicating real-world scenarios. These controlled environments provide safe spaces for developing coping mechanisms under professional supervision. Realistic scenario immersion enables patients to achieve deeper understanding of behavioral triggers and response patterns, facilitating substantive behavioral modification. Therapists can tailor each simulation to address individual patient needs with remarkable precision.

The Role of Technology and Innovation in Facilitating Deconstruction

Technological Advancements in Material Analysis

Cutting-edge analytical technologies have revolutionized deconstruction processes through non-destructive material evaluation. Advanced imaging systems including 3D laser scanning and infrared spectroscopy enable comprehensive assessment of structural integrity and material composition without physical sampling. This data informs optimal disassembly strategies, ensuring safe material extraction while maximizing salvage potential. Such technological integration transforms deconstruction from crude demolition to precision resource recovery operations.

Modern material characterization instruments provide unprecedented insight into physical and chemical properties. These analytical capabilities enable informed decisions regarding material repurposing, recycling pathways, or responsible disposal. Understanding molecular composition, mechanical properties, and environmental impact profiles proves essential for sustainable deconstruction practices that minimize ecological harm while recovering maximum value.

Innovative Approaches to Dismantling Structures

Structural deconstruction methodologies continue evolving through technological innovation. Robotic dismantling systems now perform precise material separation with millimeter accuracy, particularly valuable for hazardous material handling. These automated solutions enhance worker safety while preserving nearby structural elements, significantly improving material recovery rates and project timelines.

Specialized deconstruction tools complement robotic systems, featuring advanced cutting, separating, and lifting mechanisms. These purpose-built instruments enable careful component extraction without compromising material integrity, dramatically reducing construction waste generation while maintaining reusable material quality.

Sustainable Material Recovery and Recycling Systems

Effective deconstruction depends on sophisticated material recovery infrastructure. Modern sorting technologies employ sensor-based separation, automated grading, and specialized processing to segregate wood, metals, polymers, and masonry materials. This systematic approach creates circular material flows, reducing virgin resource consumption while establishing sustainable construction ecosystems.

The Role of Design and Engineering in Deconstruction Planning

Strategic deconstruction requires meticulous pre-planning. Forward-looking design principles facilitate optimized material recovery through selective dismantling sequences. Engineers now develop structures with inherent deconstruction capabilities, incorporating modular assemblies and reversible connection systems. Such design philosophies reduce labor requirements while minimizing community disruption, representing the future of sustainable construction practices.