The Role of AI in Optimizing Circular Fashion Processes

- Introduction: Characterized by heavy R&D investment and awareness-building

- Growth: Marked by accelerating sales and increasing competition

- Maturity: When sales plateau and differentiation becomes critical

- Decline: The inevitable phase of reduced demand

Each transition between phases requires strategic reassessment. For instance, pricing strategies that work during rapid growth often prove ineffective when markets mature and alternatives proliferate.

Strategies for the Introduction Phase

Launching a product successfully demands more than just creating awareness. The most effective introductions create emotional connections with early adopters while clearly demonstrating unique value propositions. Consider Tesla's early marketing - they didn't just sell electric cars, they sold membership in an environmental movement with cutting-edge technology.

Early customer feedback loops are equally crucial. Companies like Dropbox and Slack famously used beta testing periods to refine their offerings based on real user experiences. This iterative approach helps identify potential pain points before full-scale production begins.

Managing the Growth Phase

Scaling effectively during periods of rapid expansion separates market leaders from also-rans. Operational excellence becomes paramount - supply chains must flex to meet demand surges while maintaining quality standards. The most successful companies use growth phases to establish competitive moats through network effects, brand loyalty, or proprietary technologies.

Distribution strategy often requires reevaluation during growth. What began as direct online sales might need supplementation with retail partnerships or international expansion to capture additional market segments.

Strategies for the Maturity Phase

When markets saturate, innovation shifts from product features to business model adaptation. Consider how Apple transformed the maturing smartphone market by expanding into services like Apple Music and iCloud. Successful companies find ways to increase customer lifetime value through complementary offerings and ecosystem development.

Cost optimization becomes critical during maturity. Process improvements, supply chain refinements, and operational efficiencies can maintain profitability even as competitive pressures increase margins.

Addressing the Decline Phase

Not all products warrant continued investment when decline begins. Strategic pruning of underperforming SKUs can free resources for more promising opportunities. However, some products can find new life through repositioning - witness the resurgence of vinyl records in the digital age.

Harvesting strategies require careful calibration. Reducing marketing spend too aggressively might accelerate decline, while maintaining excessive inventory risks obsolescence costs. The most effective approaches phase out products in sync with natural replacement cycles.

The Future of Circular Fashion: AI-Driven Innovation

AI-Powered Material Selection and Design

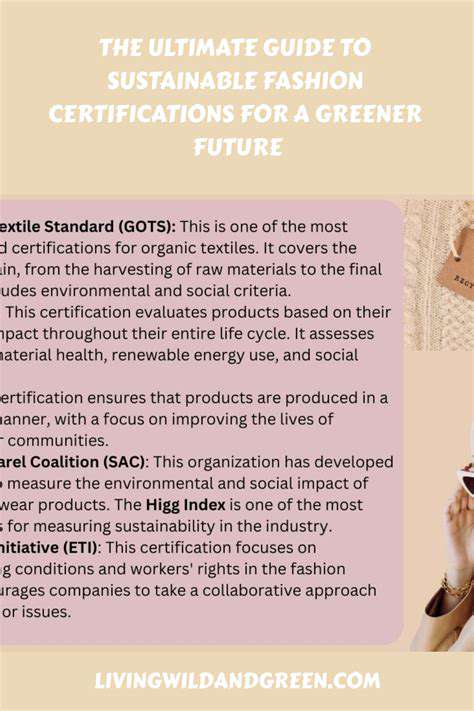

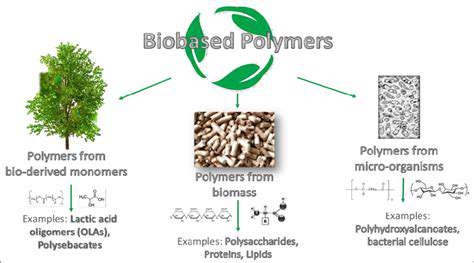

The fashion industry stands on the brink of a sustainability revolution powered by intelligent systems. Modern AI platforms can analyze thousands of material properties in seconds, comparing environmental impacts, durability metrics, and ethical sourcing data. This capability enables designers to make informed choices that balance aesthetic, functional, and sustainability considerations from the earliest design stages.

Predictive modeling takes this further by simulating how materials will perform under various conditions. Designers can identify potential weaknesses before production begins, reducing the need for physical prototyping and associated waste. The result? Garments that look better, last longer, and leave lighter environmental footprints.

Predictive Analytics for Demand Forecasting

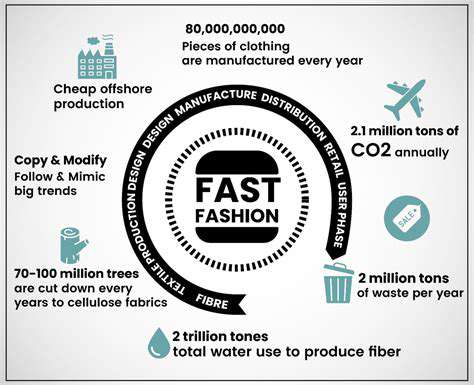

Traditional fashion forecasting relied heavily on intuition and past performance. Today's AI systems incorporate real-time data from social media, weather patterns, economic indicators, and even geopolitical events. This multidimensional analysis enables unprecedented accuracy in predicting which styles will resonate with consumers, dramatically reducing overproduction.

The benefits extend beyond waste reduction. More accurate forecasts allow for optimized production scheduling, reducing energy use and transportation emissions throughout the supply chain. Brands that master this capability gain both environmental and competitive advantages.

Personalized Fashion Experiences

AI-powered personalization transforms how consumers interact with fashion. Advanced algorithms now consider body measurements, color preferences, lifestyle factors, and even social media activity to recommend perfectly suited items. This hyper-relevance dramatically decreases return rates while increasing customer satisfaction and brand loyalty.

Virtual try-on technologies take this further, allowing consumers to visualize how garments will look and fit before purchase. The environmental benefits are substantial - fewer returns mean less transportation emissions and reduced landfill waste from unwanted items.

Optimized Supply Chain Management

Modern AI systems bring unprecedented visibility to fashion supply chains. By analyzing data from RFID tags, IoT sensors, and blockchain ledgers, these platforms can track materials from source to store. This transparency helps identify inefficiencies, ethical concerns, and opportunities for improvement across global production networks.

Predictive maintenance algorithms reduce downtime in manufacturing facilities, while route optimization minimizes transportation emissions. The cumulative impact? Faster, cleaner, and more ethical production cycles that benefit both businesses and the planet.

Sustainable Manufacturing and Waste Reduction

AI-driven process optimization is revolutionizing fashion production. Computer vision systems monitor manufacturing lines in real-time, identifying quality issues and material waste as they occur. Advanced analytics suggest adjustments that can reduce energy use by up to 30% in some textile processes.

Perhaps most exciting are AI applications in textile recycling. Machine learning algorithms can analyze discarded garments and recommend optimal recycling methods based on fiber composition, dye content, and construction. This capability is essential for creating true circularity in fashion, where old clothes become raw materials for new creations rather than landfill waste.