Sustainable Materials for Activewear: Performance and Planet: New Innovations

Plant-Based Alternatives: Nature's Answer to Performance Fabrics

Sustainable Performance Fabrics: Exploring the Potential of Plant-Based Alternatives

Plant-derived textiles are making waves in performance apparel, offering eco-friendly solutions without sacrificing functionality. Materials like hemp, bamboo, and soy present viable options that challenge traditional synthetics. Their cultivation typically demands fewer resources, and their biodegradable properties address growing waste concerns in fashion. What's more, these natural fibers demonstrate impressive capabilities, from moisture management to durability, making them adaptable for everything from yoga pants to hiking gear.

Unlike petroleum-based fabrics that contribute heavily to carbon emissions, plant-based materials provide a cleaner alternative. This shift aligns with consumer values as people become more conscious of their environmental impact. The textile industry's future may depend on harnessing nature's ingenuity through these renewable resources.

Performance Traits and Real-World Uses

Plant-based fabrics bring unique advantages to the table. Hemp stands out for its ruggedness, ideal for products requiring extra toughness. Bamboo excels at pulling moisture away from skin, perfect for intense workouts. Soy-based textiles offer a silky feel while allowing air circulation, suitable for both casual wear and specialized medical uses. These diverse qualities highlight how plant fibers can meet various performance needs.

Continuous advancements in textile technology are enhancing these materials' capabilities. Researchers are developing methods to boost water resistance and longevity, narrowing the gap with synthetic alternatives. Such improvements are critical for broader market acceptance and the evolution of sustainable sportswear. With ongoing innovation, these natural materials could redefine performance apparel standards.

The journey toward perfecting plant-based fabrics requires persistent research. Focus areas include refining production methods, strengthening material integrity, and expanding functional applications. These efforts will solidify plant fibers' position in an industry increasingly prioritizing sustainability.

Bio-Based Polymers: A New Generation of Sustainable Performance Fabrics

Understanding Bio-Based Polymers

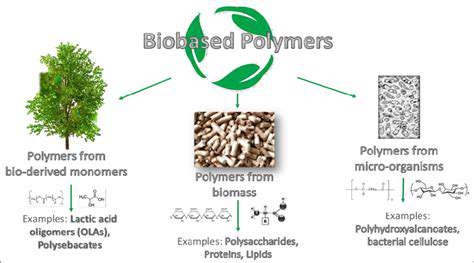

Nature-derived plastics represent an exciting frontier in sustainable materials. Sourced from plants, agricultural byproducts, and microbial processes, they reduce dependence on dwindling petroleum reserves. This transition supports environmental goals while fostering circular economic models. Beyond simply replacing conventional plastics, these innovative materials enable novel applications through their customizable properties.

Diverse Polymer Varieties

The bio-polymer family includes several notable members. PLA (polylactic acid), made from corn, is widely used for its versatility. PHAs (polyhydroxyalkanoates), produced by bacteria, offer exceptional biodegradability. Emerging options derived from wood pulp and plant structural components further expand the possibilities. Selecting the right polymer depends on specific needs—whether prioritizing flexibility, heat resistance, or other performance factors.

Environmental Advantages

Bio-polymers significantly lower carbon emissions compared to traditional plastics since they originate from renewable sources. Their reduced fossil fuel dependence presents major ecological benefits. Many variants also break down naturally, unlike conventional plastics that may persist for centuries. This decomposition capability helps mitigate waste accumulation in ecosystems.

Industry Applications

These sustainable materials are transforming multiple sectors. Packaging solutions increasingly incorporate bio-polymers for food and retail products. The medical field utilizes them for certain devices, while fashion adopts them for eco-conscious textiles. Each application demonstrates the materials' adaptability across different needs.

Overcoming Obstacles

Despite their promise, challenges remain in bio-polymer adoption. Production costs often exceed conventional plastics, limiting widespread use. Consistency in quality and performance also requires attention. Solving these issues is crucial for the technology's long-term viability. Future research will focus on refining manufacturing, enhancing material properties, and discovering new applications for these sustainable alternatives.

The Future of Sustainable Activewear: A Partnership Between Innovation and Responsibility

Material Breakthroughs

The next generation of activewear relies on groundbreaking materials that surpass conventional synthetics. Options like seaweed-based fabrics and agricultural waste polymers provide sustainability without compromising functionality. Advanced recycling methods are creating closed-loop systems where old garments become new high-performance materials. Concurrently, researchers are developing manufacturing processes that conserve resources while maintaining product quality.

Ethical Manufacturing

True sustainability extends beyond materials to encompass production ethics. Consumers increasingly demand visibility into supply chains, expecting fair labor practices and environmental stewardship. Companies must implement rigorous standards and verification systems. Supporting local economies through fair trade partnerships creates more equitable industry models while ensuring product traceability from source to store.

Thoughtful Design

Eco-conscious design minimizes waste through efficient pattern-making and durable construction. Creating garments meant to last—with repairable components—reduces replacement frequency. Educating consumers about garment care and repair options fosters responsible ownership. This shift toward longevity challenges disposable fashion mentalities.

Digital Integration

Technology optimizes sustainability across the production cycle. 3D design tools reduce material waste during prototyping, while data analytics identify efficiency improvements. Blockchain solutions enhance supply chain transparency, allowing consumers to verify product origins and manufacturing conditions. These digital tools create accountability while improving operational sustainability.

Consumer Involvement

Brands must engage customers in sustainability conversations. Clear communication about material sourcing, production impacts, and care instructions empowers informed choices. Community-building around sustainable practices encourages collective responsibility. This consumer engagement is vital for driving industry-wide change toward more responsible activewear production and consumption.