Innovative Solutions for Hard to Recycle Textiles: Breaking Barriers

Understanding the Complexity of Chemical Recycling

Chemical recycling, a burgeoning field in materials science, tackles the intricate challenge of decomposing complex materials like plastics and textiles. Unlike mechanical recycling, which physically separates materials, chemical recycling fundamentally alters the molecular structure of these materials. This process often involves breaking down the complex polymers into simpler molecules, which can then be used as feedstocks for creating new polymers or other valuable products. This approach holds tremendous potential for creating a circular economy, significantly reducing reliance on virgin resources and minimizing waste generation.

The diverse chemical structures of different plastics and other materials present a significant hurdle for chemical recycling. Polymers, the building blocks of plastics, come in a wide array of chemical compositions and molecular weights, making the degradation process highly specific and demanding. Researchers are constantly exploring new catalysts and reaction conditions to effectively break down these complex polymers without producing harmful byproducts or losing valuable chemical constituents.

Harnessing the Power of Catalysts and Solvents

A crucial component of chemical recycling is the utilization of catalysts and solvents. These agents facilitate the breakdown of complex polymers into their constituent monomers, enabling the subsequent creation of new products. Catalysts accelerate chemical reactions, allowing for more efficient and controlled decomposition. Suitable solvents are essential for dissolving the polymers, enabling the reaction to proceed effectively. The development of environmentally friendly and cost-effective catalysts and solvents is a key area of research in this field.

Different types of plastics require varying approaches. For example, certain plastics might need specific catalysts or solvents for effective decomposition, highlighting the importance of material-specific strategies. Finding optimal combinations of catalysts and solvents is crucial for efficient and economically viable chemical recycling processes. This requires significant research and development to ensure that the process is not only effective but also environmentally responsible.

Exploring the Potential of Chemical Recycling for Diverse Materials

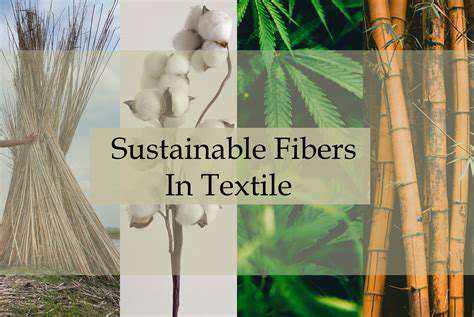

Chemical recycling is not limited to plastics. It also holds promise for the recycling of textiles, rubber, and even certain types of electronic waste. The application of chemical recycling to these diverse materials offers a way to recover valuable resources from otherwise unusable materials. This includes extracting valuable metals from electronic waste and converting textile fibers into new fibers or other products. This broad applicability showcases the potential of chemical recycling to address the global challenge of waste management and resource scarcity.

The development of specialized chemical recycling processes for specific materials is crucial for maximizing the economic and environmental benefits. Each material type has unique properties and chemical structures, demanding customized approaches to achieve efficient and sustainable recycling. This includes tailoring the chemical reactions, selecting appropriate catalysts, and optimizing the recovery of valuable components. Research in this area is rapidly evolving, leading to innovative solutions for handling the growing stream of hard-to-recycle materials.

Economic and Environmental Benefits of Chemical Recycling

Chemical recycling offers significant economic and environmental benefits compared to traditional methods. By recovering valuable resources from waste materials, it reduces the need for extracting virgin resources, leading to lower environmental impact and reduced reliance on finite resources. The creation of new products from recycled materials can stimulate economic growth and reduce the demand for raw materials, further contributing to a circular economy model. This can reduce the overall environmental footprint of product lifecycles, leading to a more sustainable future.

The economic viability of chemical recycling processes depends on factors such as the cost of raw materials, the efficiency of the recycling process, and the market value of the recovered products. While initial investment costs can be substantial, the long-term economic benefits, including reduced reliance on virgin materials, can outweigh these costs. The potential for creating new markets for recycled materials further enhances the economic attractiveness of this technology. This makes chemical recycling a promising solution for the future of materials management.