Educating Designers for a Circular Future

Integrating Circularity into Design Curricula

Understanding Circularity in Design

Circular economy principles are increasingly important in design, moving away from the traditional linear take-make-dispose model. This shift necessitates a fundamental rethinking of product lifecycles, focusing on resource efficiency, material reuse, and minimizing waste. Designing for disassembly and material recovery is key to achieving a truly circular system. This involves considering the entire lifecycle of a product, from raw material extraction to end-of-life processing, to identify and mitigate environmental impacts.

The goal is to create products that can be easily repaired, reused, or recycled at the end of their useful life. This reduces reliance on virgin materials and minimizes the environmental burden associated with waste disposal. By incorporating circular design principles from the outset, designers can contribute to a more sustainable future.

Material Selection and Sourcing

Sustainable material selection plays a crucial role in circular design. Choosing recycled or renewable materials over virgin resources is essential to reducing environmental impact. This involves evaluating the environmental footprint of various materials and prioritizing options with lower embodied energy and carbon emissions. Careful consideration needs to be given to the entire lifecycle of the material from extraction to disposal.

Sourcing materials ethically and responsibly is equally important. Transparency in the supply chain is crucial to ensure that materials are sourced from sustainable and fair practices. This includes considering factors such as labor conditions, environmental regulations, and social responsibility throughout the supply chain.

Product Design for Durability and Reparability

Designing for durability and repairability is critical to extending the lifespan of products. Products should be built to last, with robust components and user-friendly repair instructions, thereby increasing their lifespan. This approach reduces the need for frequent replacements and minimizes waste.

Features like modular designs and standardized components facilitate easier disassembly and repair. This allows for easier component replacement and reduces the need for complete product replacements. These design choices can lead to significant reductions in material consumption and waste generation.

Designing for End-of-Life Recovery

Considering the end-of-life phase of a product is crucial for successful circular design. Designers should proactively plan for the recovery and reuse of materials and components. This includes designing for disassembly, specifying materials suitable for recycling or composting, and identifying potential reuse applications for components.

Clear labeling and documentation of materials and manufacturing processes can aid in efficient material recovery and recycling processes. This information helps in identifying material types and guiding the recycling process. This information is essential for the efficient end-of-life processing of the products.

Lifecycle Assessment and Impact Analysis

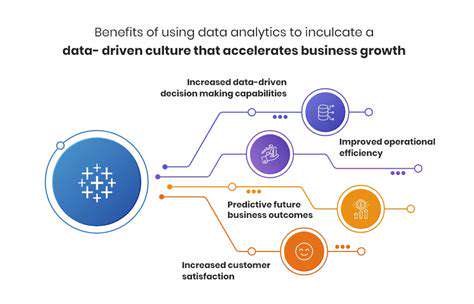

Conducting a comprehensive lifecycle assessment (LCA) is essential to understanding the environmental impact of a product throughout its entire lifecycle. This involves evaluating the environmental impacts of raw material extraction, manufacturing, use, and end-of-life disposal. Data from LCA analyses can help identify areas for improvement and guide design decisions.

Analyzing the potential impacts of a product's design choices on the environment and society can help in making informed decisions about sustainable practices. This analysis should encompass the entire product lifecycle to ensure comprehensiveness and transparency. This allows designers to make informed decisions to mitigate environmental impacts.

Collaboration and Stakeholder Engagement

Successful circular design requires collaboration across various stakeholders. Collaboration between designers, manufacturers, consumers, and policymakers is essential. This collaborative approach can facilitate the development and implementation of effective circular solutions.

Engaging with consumers throughout the design process is crucial for understanding their needs and preferences. This allows for the creation of products that meet their needs while minimizing environmental impact. This will help in creating products that customers will value and use sustainably.

Developing Skills for Circular Design Thinking

Understanding the Circular Economy Principles

The circular economy is a systemic approach to developing economies that prioritizes resource efficiency and minimizes waste. It moves away from the traditional linear take-make-dispose model, aiming for a more sustainable and regenerative system. This shift requires a fundamental change in how we design, produce, and consume products and services. Circular economy principles emphasize reuse, repair, and recycling to maximize the lifespan of materials and minimize environmental impact.

Key principles include designing out waste and pollution, keeping products and materials in use, regenerating natural systems, and sharing, leasing, and reusing resources. Understanding these foundational principles is crucial for developing skills applicable in a circular economy context.

Product Design for Circularity

Circular design goes beyond traditional product design, emphasizing durability, repairability, and recyclability. It considers the entire lifecycle of a product, from raw material extraction to end-of-life disposal, aiming to minimize environmental impact at each stage. This approach requires a proactive shift in mindset, moving away from single-use products towards products designed for longevity and reuse. Innovation in materials science and manufacturing processes is essential to facilitate this transition.

Waste Management and Recycling Strategies

Effective waste management and recycling strategies are crucial components of a circular economy. These strategies must be adaptable and responsive to the specific needs of different communities and industries. Proper waste sorting and processing are essential to maximize the recovery of valuable materials and reduce landfill waste. Investing in sustainable waste management infrastructure is paramount to creating a truly circular system.

Innovative approaches to waste processing and recycling, such as advanced recycling technologies, are vital for extracting valuable resources from waste streams and reducing reliance on virgin materials.

Sustainable Supply Chain Management

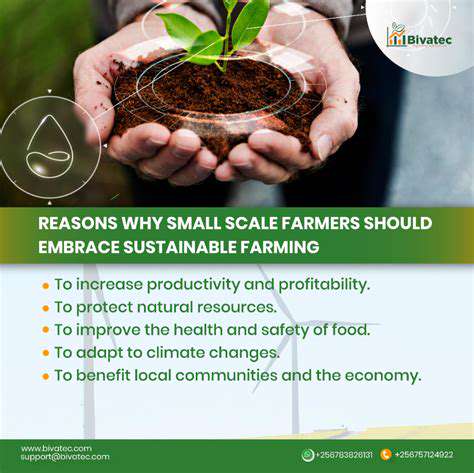

Developing sustainable supply chains is essential for a circular economy. This involves collaboration across the entire value chain, from raw material suppliers to end-users, to ensure that resources are sourced responsibly and that products are designed for circularity. Companies must prioritize ethical sourcing and transparent practices throughout the supply chain. Transparency and traceability are key to building trust and accountability. This includes assessing environmental and social impacts along the supply chain to identify and mitigate potential risks.

Resource Efficiency and Conservation

Resource efficiency and conservation are central to the principles of a circular economy. This involves minimizing resource consumption and optimizing the use of existing resources. Developing strategies for resource conservation, such as water and energy efficiency, is vital for minimizing environmental impact. Effective resource management practices can significantly reduce waste and enhance sustainability. Minimizing material consumption through product design and manufacturing processes is key.

Business Models for Circularity

New business models are needed to support a circular economy. These models can encompass product-service systems, where companies provide services rather than products, sharing economy platforms, and reuse and repair initiatives. Innovative business models can foster a more sustainable and equitable economic system. By shifting focus from ownership to access, businesses can unlock new revenue streams and reduce waste.

Policy and Infrastructure Support

Public policies and infrastructure are essential for enabling the transition to a circular economy. Government policies can incentivize circular practices, such as extended producer responsibility schemes, and support the development of necessary infrastructure for waste management and recycling. Strong policy frameworks provide the necessary environment for businesses and individuals to embrace circular principles. Investing in research and development of circular technologies and supporting entrepreneurship in this sector are crucial for success.

Promoting Collaboration and Innovation

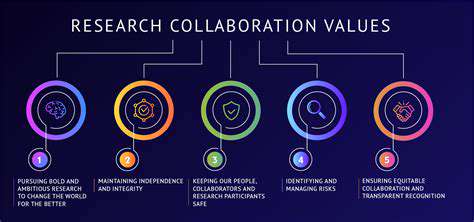

Fostering Interdisciplinary Collaboration

A crucial aspect of educating designers for a circular future is fostering interdisciplinary collaboration. Designers must move beyond their traditional silos and engage with experts from diverse fields like engineering, materials science, and environmental policy. This interdisciplinary approach allows for a more holistic understanding of the entire product lifecycle, from material sourcing to end-of-life disposal. By working alongside engineers, designers can explore innovative solutions for material efficiency and durability. Collaboration with environmental scientists enables a deeper understanding of ecological impacts and the identification of sustainable alternatives. A truly circular design approach requires a collective effort, and education must equip designers with the skills and knowledge to thrive in these collaborative environments.

Encouraging interaction between design students and professionals from related fields is vital. Guest lectures, workshops, and joint projects can bridge the gap between academia and industry. Such collaborations can illuminate real-world challenges and inspire innovative solutions. Students will benefit from exposure to diverse perspectives and learn practical skills needed to successfully navigate complex projects in the future.

Equipping Designers with Circular Design Principles

Educating designers for a circular future involves more than just introducing them to the concept; it requires equipping them with a comprehensive toolkit of circular design principles. This includes understanding the principles of material selection, product durability, and repairability. Designers should be taught to prioritize the use of recycled and renewable materials, minimize waste generation throughout the product lifecycle, and design for disassembly and reuse. These foundational principles are essential for creating products that are not only aesthetically pleasing but also environmentally responsible.

Beyond the technical aspects, designers need to develop a nuanced understanding of the social and economic implications of circularity. This means exploring the potential for new business models, like product-as-a-service and sharing economies, and understanding how design can contribute to a more equitable and sustainable future. Educating designers to consider the full lifecycle impacts of their creations, from cradle to grave, will be essential in achieving a truly circular economy.

Furthermore, the curriculum should incorporate case studies of successful circular design projects, showcasing how these principles can be applied in various contexts. Learning from real-world examples will strengthen the theoretical understanding of circular design and provide valuable insights for future projects. Students need to be given practical exercises and projects that encourage them to apply these principles to real-world problems.

Promoting a culture of continuous learning and adaptation is crucial. The circular economy is constantly evolving, and designers need to be prepared to adapt to new technologies, materials, and societal needs. The education process should not be seen as a one-time event, but rather as a continuous journey of learning and development.

Encouraging critical thinking and creativity is vital for developing the next generation of circular designers. Designing for circularity requires not just technical skills but also innovative thinking and a willingness to challenge conventional approaches. This requires fostering a creative environment in the classroom, where students are encouraged to explore unconventional solutions and develop their own unique design perspectives.

By incorporating these aspects, the education of designers can effectively nurture a new generation capable of driving innovation and collaboration toward a sustainable future.