From Production to Post Consumer: The Circular Fashion Journey

The Linear Fashion Model's Environmental Footprint

Raw Material Extraction and Processing

The linear fashion model's dependence on raw materials, primarily cotton, polyester, and synthetic fibers, has a significant environmental impact. The extraction of these materials often involves deforestation, water pollution, and the depletion of natural resources. Mining for metals used in textiles, like those used in zippers and hardware, also contributes to habitat destruction and soil erosion. Furthermore, the processing of these raw materials, often involving harsh chemicals and energy-intensive processes, releases harmful pollutants into the environment.

Manufacturing and Production Processes

The manufacturing phase of the linear fashion model encompasses a multitude of processes, from spinning and weaving to dyeing and finishing. These processes often necessitate considerable energy consumption, contributing to greenhouse gas emissions. Water pollution is another significant concern, with textile dyeing being a major contributor to water contamination. The use of pesticides and other chemicals in agriculture, a precursor to the manufacturing process, further compounds the environmental damage.

Distribution and Transportation

The globalized nature of the linear fashion model necessitates extensive transportation networks to move garments from production facilities to retail stores. This transportation often relies heavily on fossil fuels, leading to significant carbon emissions. The long distances involved in these supply chains mean increased fuel consumption and a heightened environmental burden. Furthermore, the sheer volume of transportation associated with this model contributes to congestion, noise pollution, and potential accidents.

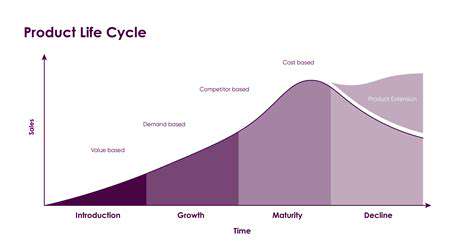

Retail and Consumption

The retail aspect of the linear fashion model often promotes fast fashion, encouraging consumers to buy more clothes than necessary. This consumption pattern directly contributes to the overproduction of textiles, which eventually results in increased waste generation. The focus on trendy, disposable styles further fuels this cycle, leading to a massive amount of discarded clothing entering landfills. This rapid turnover in styles also necessitates the continuous production of new materials, further exacerbating the environmental impact.

Waste Management and Disposal

A significant portion of the environmental footprint of the linear fashion model stems from poor waste management. The sheer volume of discarded clothing, from unsold inventory to worn-out garments, overwhelms landfill capacity. Many textiles are not easily biodegradable, and their decomposition in landfills can take centuries. The disposal of these materials often leads to land and water contamination. Recycling efforts are often insufficient to address the sheer volume of textile waste generated.

Post-Consumer Impacts

The linear fashion model's environmental footprint extends beyond production and consumption. The disposal of discarded textiles impacts ecosystems, as fibers can persist in the environment for extended periods, potentially harming wildlife. The leaching of chemicals from these materials can contaminate soil and water sources, further endangering surrounding ecosystems. The overall impact of this model necessitates a paradigm shift towards more sustainable practices in the fashion industry, from sourcing raw materials to handling post-consumer waste.

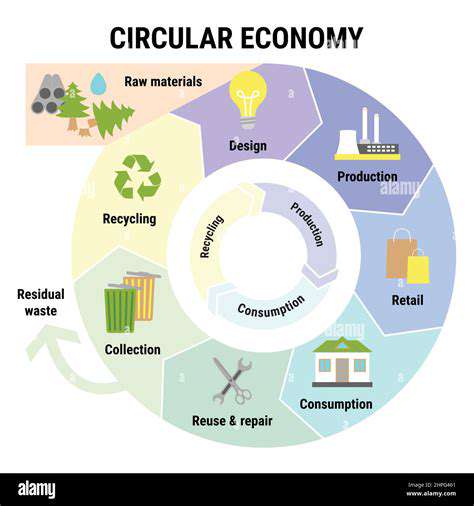

Embracing the Circular Economy in Fashion

Designing for Durability and Repurposing

The fashion industry is notoriously linear, often prioritizing fast production and frequent consumption. A crucial step towards a circular economy in fashion is designing garments for durability and longevity. This involves using high-quality, sustainable materials that can withstand repeated wear and washing, minimizing the need for frequent replacements. Innovative materials like recycled fabrics and bio-based textiles are key to this transition, offering both environmental and economic benefits. Furthermore, designing for disassembly and repurposing is essential. This means considering the garment's components and how they can be separated and reused in new products, extending the product's lifespan and reducing waste.

Beyond materials, design strategies focusing on modularity and interchangeability can also promote longevity. Think garments with detachable components like sleeves or collars that can be swapped, or pieces designed for layering to create various outfits. This adaptability not only extends the useful life of the garment but also encourages creativity and reduces the need for consumers to constantly purchase new items. By integrating these principles into the design process, the fashion industry can move away from a throwaway culture and embrace a more sustainable approach.

The Power of Transparency and Collaboration

Transparency throughout the entire fashion supply chain is paramount to fostering a circular economy. Consumers need to understand the origin of their clothes, the materials used, and the ethical practices behind their production. This transparency empowers consumers to make informed choices aligned with sustainable values. Clearly labeling garments with information about their lifecycle, including materials, origin, and potential for recycling or repurposing, is a crucial step towards greater consumer engagement and awareness.

Collaboration between designers, manufacturers, retailers, and consumers is essential. Facilitating initiatives that support the reuse and recycling of clothing is vital. This could include partnerships with repair shops, textile recycling programs, and initiatives that encourage consumers to donate or sell used garments. By promoting a collaborative approach, the fashion industry can create a more unified system for managing textile waste and promoting the circular economy's core principles.

Furthermore, supporting local manufacturers and artisans who prioritize sustainable practices helps build a more resilient and responsible fashion ecosystem. This supports local communities and promotes a conscious approach to production. These collaborations can drive innovation and pave the way for a more circular future in fashion.

Finally, investing in research and development of innovative technologies for textile recycling and upcycling is critical. This commitment to progress will enable the fashion industry to tackle the challenges associated with textile waste and contribute to a circular economy. By fostering a culture of collaboration and innovation, the industry can pave the way for a more sustainable and environmentally responsible future.

Through transparency and collaboration, the fashion industry can create a more sustainable and equitable system, where garments are designed for durability and longevity, and waste is minimized.

Innovative Materials and Production Techniques

Advanced Polymer Composites

Polymer composites are revolutionizing various industries, offering a unique blend of desirable properties. These materials, often incorporating high-performance fibers like carbon or aramid with polymeric matrices, exhibit exceptional strength-to-weight ratios, superior stiffness, and enhanced resistance to chemicals and extreme temperatures. This combination of properties makes them ideal for applications ranging from aerospace components to automotive parts, significantly reducing material weight and enhancing performance characteristics while maintaining structural integrity.

The creation of these composites involves meticulous control over the mixing and processing of the constituent materials. Advanced techniques, such as melt spinning and fiber alignment, are critical to achieving the desired mechanical properties. The careful selection of polymers and fillers directly impacts the final properties of the composite, showcasing the intricate interplay between material science and manufacturing processes.

3D Printing for Customized Manufacturing

Additive manufacturing, particularly 3D printing, is transforming production methodologies. This technology enables the creation of complex geometries and customized parts with unprecedented precision, eliminating the need for traditional tooling and molds. It's particularly beneficial in prototyping, short-run production, and on-demand manufacturing, allowing for rapid iteration and adaptation to evolving customer requirements.

3D printing facilitates the design and creation of parts that were previously impossible to produce using conventional methods. This opens up possibilities for bespoke solutions in sectors like medical implants, aerospace components, and consumer goods. The ability to manufacture components directly from digital models minimizes waste and reduces production time, making it a powerful tool in the modern manufacturing landscape.

Sustainable Manufacturing Processes

The focus on sustainability is driving the development of innovative materials and production techniques. This includes exploring bio-based polymers derived from renewable resources, minimizing waste generation throughout the manufacturing process, and optimizing energy consumption in production facilities. These practices contribute to a circular economy, reducing the environmental footprint of the manufacturing industry.

Sustainable manufacturing extends beyond the material selection. It encompasses the entire lifecycle of a product, from design and production to recycling and reuse. Implementing efficient waste management strategies and optimizing energy usage throughout the manufacturing process are crucial steps in achieving sustainable production goals. This approach is vital for reducing the overall environmental impact of products and supporting a more responsible approach to manufacturing.

Nanomaterials for Enhanced Performance

Nanomaterials are poised to revolutionize various industries with their unique properties at the nanoscale. These materials, engineered at the atomic and molecular level, exhibit enhanced strength, conductivity, and reactivity compared to their bulk counterparts. This opens up new avenues for applications in electronics, energy storage, and biomedical devices, leading to significant advancements in these fields.

The development of nanomaterials requires advanced synthesis and characterization techniques. Controlling the size, shape, and structure of nanomaterials is critical for achieving the desired properties. This intricate process emphasizes the importance of understanding the behavior of materials at the nanoscale, allowing for the creation of materials with tailored properties to meet specific performance demands. This innovative approach to material design is crucial for meeting future technological needs.

Bio-Inspired Design for Efficiency and Functionality

Nature's ingenuity offers valuable inspiration for designing efficient and functional materials and production techniques. Bio-inspired design draws from the structures and mechanisms found in living organisms, aiming to mimic their remarkable properties. This approach can lead to the development of lightweight, strong, and self-healing materials, as well as more sustainable production methods.

The study of biological systems provides valuable insights into material properties and manufacturing processes. Mimicking the hierarchical structures of bone, the self-healing mechanisms of certain organisms, or the remarkable efficiency of insect wings can inspire new solutions in various fields. This bio-inspired approach can foster a deeper understanding of natural processes and translate them into innovative solutions for engineering and manufacturing challenges.