Sustainable Fashion: Exploring the Latest Innovations

Bio-Based Materials: A Sustainable Alternative

Materials sourced from renewable origins, including plants, algae, and microbial sources, present an eco-friendly substitute for traditional petroleum-derived products. Their adoption marks a pivotal move toward lessening industrial environmental harm and decreasing reliance on diminishing resources. Embracing these materials is vital for fostering a greener tomorrow.

Manufacturing these substances typically demands less energy than conventional methods, resulting in smaller carbon emissions. This energy efficiency yields substantial ecological advantages, promoting cleaner environments and reduced atmospheric pollutants.

Sustainable Sourcing and Production

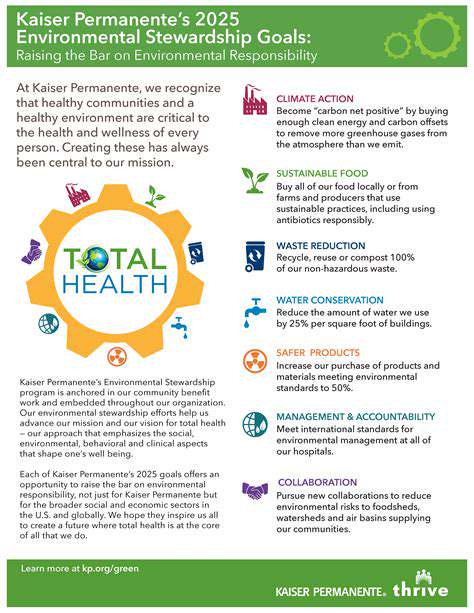

Responsible procurement of raw ingredients is fundamental in creating bio-based materials. This encompasses evaluating the full lifecycle—from growing and gathering resources to refining and production phases. An ethical strategy safeguards ecosystem vitality and avoids forest depletion or wildlife habitat damage.

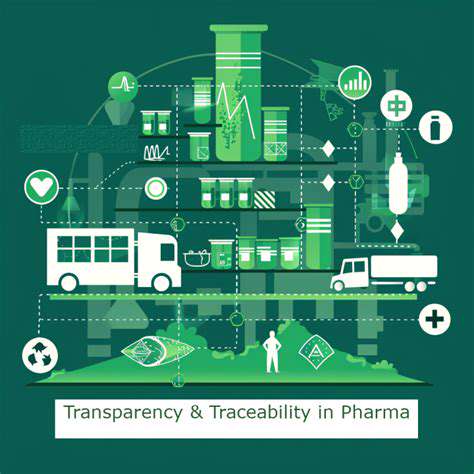

Openness and verifiable origins are critical elements of ethical procurement. Comprehensive records of material sources and processing techniques guarantee responsibility and enable validation of ecological and societal benchmarks across the supply network.

Diverse Applications Across Industries

These innovative materials find uses in multiple sectors like packaging, building, automotive, and fabric production. Their adaptability enables the creation of novel items that fulfill performance needs while reducing ecological consequences.

From compostable polymers to plant-derived adhesives, these substances provide intriguing opportunities for developing more planet-conscious goods.

Environmental Benefits and Considerations

Utilizing bio-based materials offers various ecological advantages. They decrease fossil fuel dependence, reduce contamination, and support biological diversity. By redirecting refuse from disposal sites, these materials additionally limit environmental damage.

Nevertheless, thoughtful analysis is required regarding production energy requirements, cumulative carbon output, and possible landscape alterations. Comprehensive environmental impact studies prove essential for assessing these materials' true sustainability across their complete existence cycle.

Performance and Functionality

Continuous advancements are enhancing these materials' characteristics and usefulness to satisfy varied application demands. Investigative efforts concentrate on boosting traits like resilience, longevity, and decomposability.

Researchers are refining these substances to equal or exceed conventional options' performance, broadening their potential implementations across industries.

Economic Opportunities and Challenges

Adopting bio-based materials creates substantial financial prospects for agricultural, processing, and manufacturing sectors. Progress in this domain generates employment and energizes bioeconomic expansion.

Yet economic hurdles persist, including cost comparisons with traditional materials, feedstock accessibility, and the necessity for supportive regulations and infrastructure development.

Future Trends and Research

Ongoing investigations aim to boost production effectiveness, widen material uses, and improve substance qualities. Investigating unconventional feedstocks and perfecting manufacturing techniques remain primary research focuses.

Establishing more ecological and economical production methods is imperative for broader bio-based material acceptance. Such developments will propel innovation and establish a more sustainable economic model.

Advanced Recycling Technologies: Transforming Waste into Resources

Advanced Material Recovery

Modern recycling methods now emphasize substance reclamation beyond simple waste sorting. Sophisticated techniques like molecular disassembly decompose intricate polymers into fundamental components. This enables retrieval of valuable molecular units for manufacturing new materials, decreasing virgin resource needs and waste accumulation.

Chemical Recycling Processes

Molecular reprocessing represents a significant technological leap. Thermal decomposition and gas conversion techniques employ heat and catalysts to simplify plastic refuse. These processes breathe new life into materials once deemed unrecyclable, expanding sustainable textile possibilities.

The primary benefit lies in extracting useful chemicals from diverse plastics, including those resistant to mechanical recycling. This capability fosters production of premium recycled materials, advancing circular economic principles.

Bio-Based and Biodegradable Materials

Creating plant-derived, naturally decomposable substances is essential for eco-conscious apparel industries. These renewable materials can be engineered to degrade organically, reducing clothing's environmental toll. This method lessens petroleum dependence and establishes sustainable material lifecycles.

Enhanced Sorting and Separation Techniques

Refined classification methods form the foundation of effective recycling. Cutting-edge optical scanning and electromagnetic separation technologies precisely identify and isolate different materials. This improves recyclable material recovery rates while minimizing impurities, elevating reprocessed resource quality.

These separation breakthroughs prevent valuable materials from being discarded due to contamination, substantially boosting overall recycling productivity.

Upcycling and Design for Recyclability

Creative repurposing plays a major role in sustainable fashion by converting discarded textiles into premium products. This approach involves innovative redesigns that prolong material usefulness and minimize waste. Engineering items for easy disassembly and recycling is equally important for establishing sustainable product lifecycles.

Technological Advancements in Textiles

Progress in fabric production technologies significantly impacts sustainable fashion. Novel fiber creation methods incorporating recycled content reduce dependence on new resources. Introducing easily recyclable fibers in apparel manufacturing could dramatically decrease textile waste in landfills.

Consumer Engagement and Education

Public involvement and awareness are crucial for advanced recycling success. Informing consumers about recycling benefits and sustainable material choices can stimulate demand for eco-friendly products. Simplifying and clarifying recycling procedures encourages broader participation in circular fashion initiatives.