The Future of E commerce: Sustainable Fashion and Online Retail

Transparency in E-commerce

Transparency is paramount in fostering trust in the online marketplace. Consumers are increasingly demanding detailed information about the products they purchase, from the manufacturing process and materials used to the ethical treatment of workers throughout the supply chain. This requires e-commerce platforms to be proactive in providing comprehensive product information, including certifications, sustainability reports, and origin details. A transparent approach, including clear labeling and readily accessible information, builds consumer confidence and allows them to make informed decisions aligning with their values. This transparency also extends to pricing, shipping costs, and return policies. By embracing transparency, e-commerce businesses can cultivate a loyal customer base and enhance brand reputation in the long run.

Moreover, transparency extends beyond product information to encompass the entire transaction process. Clear and concise details about payment methods, security protocols, and privacy policies are crucial. By clearly outlining these aspects, e-commerce platforms demonstrate their commitment to responsible practices and protect consumers from potential scams or fraudulent activities. This proactive approach to transparency is vital in the fight against online fraud and builds a stronger sense of security for consumers, paving the way for a more robust and trusted online shopping experience.

Traceability: From Farm to Consumer

Traceability, closely linked to transparency, allows consumers to follow the journey of a product from its origin to their doorstep. This detailed tracking, often achieved through blockchain technology, helps consumers understand the origins of the goods they purchase, and ensures that products meet ethical and sustainable standards. For example, knowing the exact farm where coffee beans were grown or the specific factory where clothing was manufactured empowers consumers to make conscious choices aligned with their values. This transparency and detailed origin information are particularly important in the food industry and other sectors where the supply chain is complex.

Traceability also plays a vital role in combating counterfeiting. By providing detailed information about the product's journey, businesses can help consumers identify authentic items and protect themselves from fraudulent products. This verification process, enabled by technology, creates a more secure and trustworthy marketplace for both consumers and businesses. Furthermore, traceability empowers businesses to address supply chain issues and maintain accountability, reducing the risk of ethical concerns and environmental damage throughout the process. This approach builds a more sustainable and trustworthy e-commerce ecosystem.

Implementing traceability mechanisms can require significant investment in technology and infrastructure, but the long-term benefits are substantial. Consumers are increasingly willing to pay a premium for products with verifiable origins and ethical production processes. Traceability is not just a trend; it's a crucial element in building a sustainable and ethical future for e-commerce.

The combination of transparency and traceability fosters trust and empowers consumers to make informed decisions. This is not just about building brand loyalty; it's about creating a more ethical and sustainable e-commerce ecosystem.

By showcasing the origin and production process of goods, businesses can enhance the customer experience and strengthen their brand reputation. Consumers are more likely to support businesses demonstrating a commitment to ethical and sustainable practices.

Innovative Materials and Production Methods: Embracing Circularity

Advanced Polymer Composites

Polymer composites are revolutionizing various industries by offering a unique blend of strength, lightness, and durability. These materials are particularly appealing for applications demanding high performance at reduced weight, such as aerospace and automotive components. The ability to tailor the properties of these composites through precise material selection and processing techniques opens up a vast array of possibilities for enhancing product performance and reducing manufacturing costs.

By combining polymers with reinforcing fillers like carbon fiber or glass fiber, engineers can achieve remarkable improvements in mechanical properties. This combination results in materials that are significantly stronger and stiffer than traditional polymers alone, while maintaining a relatively low density. This combination of properties makes them ideal for a range of demanding applications.

3D Printing Technologies

Additive manufacturing, particularly 3D printing, is transforming the landscape of material production. This technology enables the creation of complex geometries and intricate designs that were previously impossible to produce using traditional methods. The ability to fabricate customized parts directly from digital models significantly reduces lead times and prototyping costs, while also fostering greater design freedom.

3D printing allows for the use of a wider range of materials, including metals, polymers, and ceramics. This versatility expands the range of applications for additive manufacturing, from rapid prototyping and customized medical implants to the production of functional parts for aerospace and automotive industries.

Sustainable Manufacturing Processes

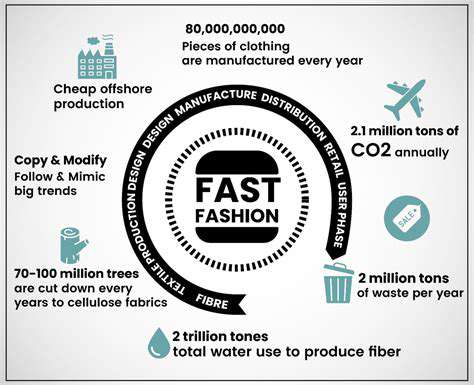

Sustainable manufacturing practices are becoming increasingly crucial in today's world. The focus is now on minimizing environmental impact and maximizing resource efficiency throughout the entire production lifecycle. This means employing techniques that reduce waste, conserve energy, and utilize renewable resources wherever possible.

Implementing these practices can lead to significant reductions in carbon emissions and waste generation, contributing to a more environmentally responsible manufacturing sector. These initiatives also enhance the company's reputation and build trust with environmentally conscious consumers.

Nanomaterials and Their Applications

Nanomaterials, with their unique properties at the nanoscale, hold immense potential for various applications across diverse industries. These materials exhibit extraordinary properties, such as enhanced strength, conductivity, and reactivity, that often surpass those of their bulk counterparts. This makes them ideal for applications demanding high performance, such as in electronics, energy storage, and biomedical devices.

The ability to manipulate materials at the nanoscale allows for the creation of novel functionalities. This opens up possibilities for developing advanced sensors, catalysts, and drug delivery systems with improved efficiency and effectiveness. This precision manufacturing also paves the way for revolutionizing existing industries.

Bio-Based Materials and Processes

The increasing demand for eco-friendly solutions has spurred the development of bio-based materials and manufacturing processes. These materials are derived from renewable sources, such as plants and agricultural byproducts, rather than fossil fuels. This reduces reliance on finite resources and lowers the environmental footprint of production. The use of bio-based materials is gaining traction in various sectors, including packaging, construction, and automotive industries.

The development of bio-based plastics, composites, and coatings is rapidly progressing. These materials offer a sustainable alternative to traditional petroleum-derived materials, presenting significant opportunities for reducing environmental impact while maintaining desired performance characteristics. This shift toward bio-based materials represents a crucial step towards a more sustainable future.