Sustainable Fashion in the Digital Age: Harnessing Technology for Good

The Rise of Sustainable Practices

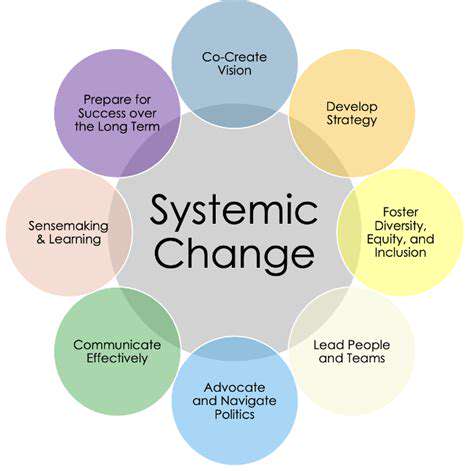

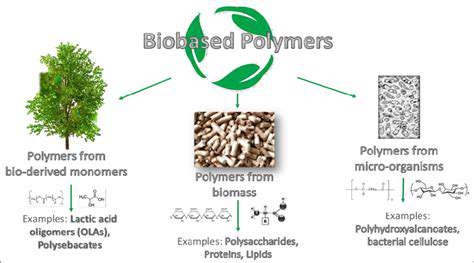

Fashion's digital transformation is fundamentally altering how the industry operates, with sustainability now at its core. Brands are ditching fast-fashion models in favor of eco-friendly materials and ethical production methods. This isn't merely about cutting waste - it represents a complete overhaul of traditional supply chains to prioritize fair labor and minimize environmental harm. The result? A fashion landscape where transparency isn't just valued - it's demanded.

Today's shoppers scrutinize purchases more carefully than ever before. With social media exposing manufacturing practices and documentaries revealing industry impacts, consumers now vote with their wallets. This shift has forced even major retailers to completely rethink their business models from the ground up.

Enhanced Transparency in Supply Chains

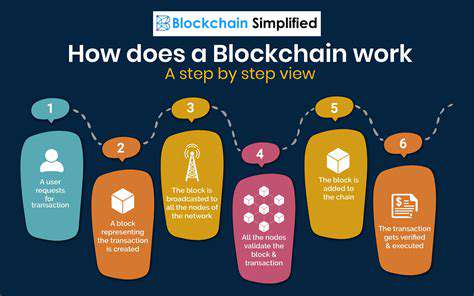

Modern tracking technologies now let brands document a garment's journey in unprecedented detail. Blockchain solutions, for instance, create immutable records from cotton field to clothing rack. Shoppers can scan QR codes to see factory conditions, material sources, and even worker testimonials - creating accountability that simply didn't exist five years ago.

This visibility revolution enables conscious consumers to easily distinguish genuine sustainability efforts from greenwashing. When every step is documented, brands can't hide behind vague eco-friendly claims without proof to back them up.

Traceability: From Farm to Fashion

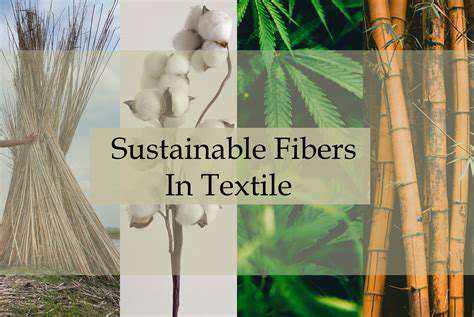

The new era of traceability goes beyond basic supply chain mapping. Advanced systems now track individual fabric lots through each processing stage, linking finished garments back to specific farms. Farmers markets increasingly partner with fashion brands, allowing customers to literally meet the growers behind their organic cotton tees.

This granular tracking reveals uncomfortable truths about water consumption and chemical use, forcing the industry to confront its environmental impact head-on. When a brand can pinpoint exactly which cotton fields used unsustainable irrigation, they can work directly with farmers to implement better practices.

Digital Design and Prototyping

Design software has revolutionized creation workflows. Where physical samples once required weeks and wasted materials, 3D prototyping now lets designers perfect fits digitally before cutting a single thread. This shift has slashed sample waste by up to 80% for early adopters while dramatically speeding up development cycles.

The collaborative benefits are equally transformative. Design teams in New York can instantly share virtual prototypes with factories in Vietnam, eliminating shipping delays and reducing the need for international travel.

Personalized Fashion Experiences

AI-powered customization is redefining made-to-order fashion. Algorithms analyze individual body scans and style preferences to suggest perfectly tailored pieces. Some brands now produce garments only after purchase, virtually eliminating overstock and the resulting waste that plagues traditional retailers.

E-commerce and Sustainable Consumption

Online shopping platforms have become sustainability game-changers. Advanced AR fitting rooms reduce returns by 25-40%, while digital resale markets extend clothing lifespans significantly. Some innovators are even experimenting with digital-only clothing - virtual garments for social media that require no physical production at all.

The Future of Fashion: A Connected Industry

As IoT sensors, AI, and blockchain mature, we're moving toward self-reporting garments that track their own lifecycle. Imagine a sweater that records its washing frequency or a bag that alerts when it needs repair. This level of connectivity could finally close the loop on circular fashion economies.

E-commerce and Sustainable Consumption: Empowering Conscious Consumers

Understanding the Rise of Conscious Consumption

The shifting consumer mindset reflects deeper societal changes. Millennials and Gen Z shoppers increasingly view purchases as political statements, favoring brands that align with their values. This isn't fleeting idealism - studies show these cohorts will pay 10-15% premiums for verified sustainable products.

E-commerce's Role in Facilitating Sustainable Choices

Online marketplaces aggregate sustainability certifications in ways physical stores can't. Filter options now include organic certified, fair trade, and carbon neutral - making ethical shopping as easy as clicking a button. Some platforms even display real-time environmental impact metrics beside each product.

The Importance of Transparency and Traceability

Forward-thinking brands now embed NFC chips in garment tags. Tapping a smartphone reveals the item's complete journey - from farm coordinates to factory audit reports. This level of detail transforms shopping from transactional to educational, helping consumers understand the true cost behind price tags.

Sustainable Packaging and Shipping Practices

Innovations here go beyond recycled boxes. Mushroom-based packaging decomposes in weeks, while plant-based inks replace toxic dyes. Some brands incentivize slower shipping for carbon savings, offering loyalty points to eco-conscious customers willing to wait.

Supporting Local and Small Businesses

Hyperlocal e-commerce platforms connect consumers with artisans within 50 miles. These micro-supply chains slash transportation emissions while preserving traditional craftsmanship that fast fashion nearly erased.

The Impact on Consumer Behavior

The transparency revolution created a self-reinforcing cycle: as more consumers demand sustainability data, more brands provide it - which in turn educates more consumers. This virtuous circle is permanently altering retail economics.

Challenges and Future Directions

The next frontier involves standardizing sustainability metrics across platforms. Without unified standards, eco-friendly remains open to interpretation. Industry consortiums are now developing blockchain-based verification systems to prevent greenwashing at scale.

Virtual Fashion Shows and Digital Design: Reducing Carbon Footprint and Expanding Accessibility

Virtual Fashion Shows: A New Era of Presentation

The pandemic accelerated virtual shows from novelty to necessity. What began as crisis management revealed unexpected benefits: digital shows attract 3-5x more viewers than physical events while costing 80% less to produce. Designers now treat digital runways as creative canvases - one recent show transformed models into floating holograms in a zero-gravity environment.

Digital Experiences and Immersive Environments

Cutting-edge shows blend gaming tech with fashion. Attendees navigate digital venues as avatars, examining garment details up close without crowding runways. Some brands create persistent virtual worlds where collections remain viewable indefinitely, unlike ephemeral physical shows.

Global Reach and Accessibility

Digital democratization has been profound. A student in Nairobi now accesses the same front-row experience as editors in Paris. Closed captioning and audio descriptions make shows accessible to disabled audiences previously excluded from fashion events.

Sustainability and Environmental Impact

The carbon math is compelling: a single international fashion week generates emissions equal to 1,200 transatlantic flights. Digital alternatives eliminate this footprint while allowing brands to reallocate budgets from logistics to innovation.

Technological Advancements and Innovation

Real-time rendering engines now showcase fabric movement with physics-accurate simulation. AI-powered personalization tailors shows to individual viewers - highlighting pieces matching their style history. The most advanced platforms use volumetric capture to create photorealistic 3D models viewable from any angle.

The Future of Fashion Presentation

The industry is converging on hybrid models - intimate physical events for tactile experiences complemented by expansive digital extensions. As VR hardware improves, front rows may transition entirely to virtual spaces where attendees from six continents can mingle as realistically as in person.