Consumer Engagement in Circular Fashion Initiatives

Resale programs, where people sell their used items for store credit or cash, create a circular economy that benefits both individuals and companies. For consumers, these programs offer a way to recover some of their initial investment while adopting a more sustainable approach to buying. They also make it easier for shoppers to afford new products, encouraging smarter spending habits.

Accessibility and Convenience: Key Factors for Consumer Engagement

To increase involvement in repair and resale programs, businesses must focus on making them accessible and convenient. This means providing clear information about how the programs work, simple instructions for participation, and user-friendly online platforms for buying and selling used goods. Local repair shops and resale centers will also be vital, offering physical locations for consumers to engage with these services.

Financial Incentives and Rewards: Motivating Consumer Participation

Financial perks can significantly drive participation in repair and resale programs. Discounts on future purchases, loyalty points, or gift cards can sway consumers to choose repair over replacement. Resale programs should also offer fair prices for both sellers and buyers to ensure a positive experience for everyone involved.

Educating Consumers About the Environmental Benefits

Teaching consumers about how their choices affect the environment is key to fostering a repair and resale culture. Highlighting the reduction in waste, conservation of resources, and lower carbon emissions linked to these practices can help people see the long-term value in choosing repair and resale. Raising awareness about product lifecycles and their environmental impact will also promote more mindful consumption.

Building Trust and Transparency in Repair and Resale

Trust and transparency are critical for the success of repair and resale programs. Consumers need to feel confident that repair services are dependable and that the resale process is fair and secure. Clear communication about repair quality, warranties, and seller verification processes is essential to building this trust. Openness about pricing and business practices will also play a major role in gaining consumer confidence.

The Role of Government and Industry Collaboration in Promoting Participation

Government policies and industry partnerships can greatly encourage consumer participation in repair and resale programs. Regulations that support repairs and discourage waste, along with subsidies for repair services, can create a favorable environment. Collaborations between businesses can lead to shared knowledge, best practices, and standardized repair methods, making these sustainable practices more appealing to consumers. This coordinated effort can streamline processes and ensure long-term success.

Designing Products for Durability and Longevity: A Consumer-Centric Approach

Understanding the Importance of Durability

Durability isn't just a nice-to-have feature—it's a cornerstone of a product's success and longevity. A well-built product not only meets immediate needs but also delivers lasting value, fostering customer loyalty and reducing the environmental harm caused by frequent replacements. This is particularly relevant today, as consumers grow more aware of the ecological footprint of their purchases.

Durability also means cost savings for manufacturers and buyers alike. Using high-quality materials and thoughtful design can minimize the need for repairs and replacements, lowering the total cost of owning the product over time.

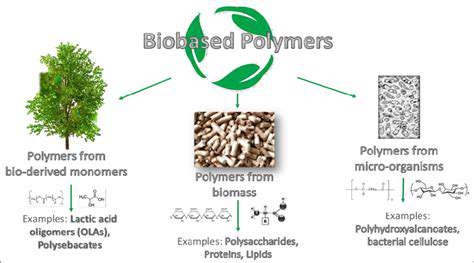

Material Selection and Engineering

The materials used in a product play a huge role in its durability. Engineers must carefully assess factors like strength, flexibility, wear resistance, and resilience to environmental conditions such as moisture and temperature changes. Choosing the right materials isn't just about price—it's about ensuring the product can endure its intended use and remain functional for years.

Smart engineering is equally important. Precise calculations and simulations help predict how a product will handle stress and strain during use. Advanced design tools and rigorous testing are key to achieving this.

Design for Manufacturing (DFM)

DFM principles are crucial for making durable products efficiently and affordably. Simplifying the manufacturing process cuts costs while maintaining quality, both of which are vital for staying competitive. Factors like assembly methods, tooling needs, and production constraints must be considered early in the design phase to enhance durability.

Features like interchangeable components, standardized parts, and easy maintenance make repairs simpler and cheaper. These elements also extend the product's lifespan and lessen its environmental impact.

Testing and Validation

Rigorous testing is non-negotiable for proving a product's durability. Tests should mimic real-world conditions to see how the product holds up under stress. Real-world testing is indispensable for understanding a product's performance in everyday use. Methods like stress tests, vibration tests, and environmental exposure tests help ensure reliability.

The data from these tests can refine designs and manufacturing processes. By spotting weaknesses early, companies can address them proactively, resulting in a sturdier final product.

Product Lifecycle Considerations

Durability isn't just about the initial design—it's about the entire lifecycle. Repairability, recyclability, and potential for reuse or refurbishment all matter. Today's market increasingly values products with minimal environmental impact and strong social responsibility.

Designing for longevity means choosing materials and features that support repairs and recycling. This sustainable approach reduces waste and aligns with growing consumer demand for eco-friendly products.

Meeting Customer Needs and Expectations

At its core, durability is about customer satisfaction. Reliable products inspire confidence and loyalty, leading to happier customers and stronger brands. Understanding the target audience's needs is critical. Products built to last under everyday or extreme conditions will naturally appeal more.

By focusing on durability, companies can deliver greater value and build a reputation for quality. This creates a cycle of trust, driving sales and brand recognition over time.