The Role of Brands in Advocating for Responsible Material Sourcing

Building Trust in Supply Chains

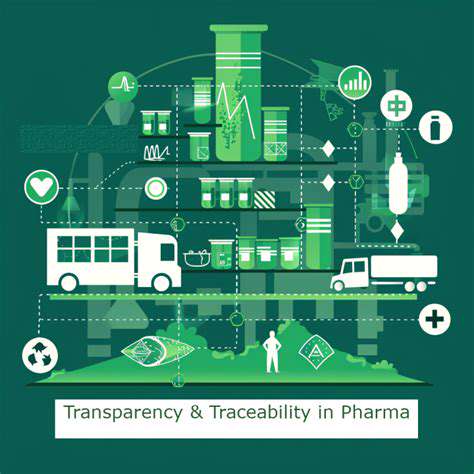

Transparency and traceability are crucial for building trust in modern supply chains. Consumers are increasingly demanding greater visibility into where their products come from and how they are made. This demand stems from a desire to understand the ethical and environmental impacts of their purchases, as well as to support sustainable and responsible practices. By providing greater transparency, companies can foster trust and loyalty among their customer base.

Enhanced Product Safety

Traceability systems allow for quicker and more effective responses to product safety issues. When a problem arises, knowing exactly where a product originated and all the steps it underwent during production enables swift identification and recall of potentially hazardous goods. This proactive approach safeguards consumers and minimizes reputational damage.

Furthermore, detailed records of materials and processes can help pinpoint the source of contamination or defects, facilitating quicker resolution and preventing future incidents.

Improved Efficiency and Cost Savings

Implementing robust traceability systems can streamline supply chain operations. Real-time tracking of goods and materials eliminates delays and reduces the risk of errors. This efficiency translates into substantial cost savings by minimizing waste, optimizing inventory management, and facilitating faster order fulfillment.

Sustainable Practices and Environmental Impact

Transparency in supply chains plays a vital role in promoting sustainable practices. By providing detailed information about the environmental footprint of each stage of production, businesses can identify areas for improvement and implement more sustainable manufacturing processes. This includes reducing waste, minimizing environmental impact, and ensuring compliance with environmental regulations.

Improved Supplier Relationships

Traceability fosters stronger and more transparent relationships with suppliers. Open communication and data sharing facilitate collaboration and trust, empowering suppliers to participate actively in upholding ethical standards and promoting sustainable practices throughout the supply chain. This collaborative approach benefits both businesses and their suppliers, fostering mutually beneficial partnerships.

Regulatory Compliance and Risk Mitigation

Many industries are subject to stringent regulations regarding product origin, safety, and labeling. Traceability systems provide a crucial mechanism for demonstrating compliance with these regulations. This documentation reduces the risk of penalties and legal challenges. Accurate records are essential for proving adherence to industry standards, ensuring business continuity, and mitigating potential risks.

Consumer Confidence and Brand Loyalty

Consumers are more likely to trust and remain loyal to brands that demonstrate transparency and accountability in their supply chains. By showcasing their commitment to ethical and sustainable practices, companies can build a stronger brand image and foster enduring customer relationships. This demonstrable commitment to traceability and sustainability resonates deeply with modern consumers, resulting in increased brand loyalty and positive brand perception.

Investing in Sustainable Materials and Processes

Investing in Sustainable Materials

Sustainable materials are crucial for brands committed to environmental responsibility. This involves sourcing materials from ethical and environmentally conscious suppliers, minimizing waste throughout the production process, and prioritizing recycled or renewable resources. Brands must carefully evaluate the entire lifecycle of a material, from extraction to disposal, to ensure its sustainability and reduce its environmental impact. This commitment extends to the selection of fibers, plastics, metals, and other components, considering their impact on water usage, deforestation, and pollution levels.

Choosing sustainable materials isn't just about eco-friendliness; it's also about building brand reputation and attracting environmentally conscious consumers. Transparency in the sourcing and production of these materials is paramount, allowing consumers to understand the ethical considerations behind their purchases. This transparency fosters trust and loyalty, ultimately benefiting the brand's long-term success.

Optimizing Production Processes

Sustainable practices extend beyond material selection. Brands should optimize their production processes to minimize environmental harm. This includes reducing water consumption, minimizing waste generation, and adopting energy-efficient technologies. Implementing lean manufacturing principles can help streamline production, decrease resource use, and reduce the environmental footprint of each product.

Reducing Waste and Pollution

Minimizing waste is a critical aspect of sustainable production. Brands can achieve this through design for durability and recyclability, implementing closed-loop systems, and promoting product reuse and repair initiatives. This proactive approach to waste management not only reduces pollution but also creates opportunities for innovation and cost savings.

Embracing Circularity

Moving towards a circular economy model is essential for sustainable practices. Brands can design products with a longer lifespan, enabling reuse and repair, and facilitating the collection and recycling of materials at the end of their useful life. This approach minimizes the reliance on virgin resources and keeps materials within the economic system for as long as possible.

Transparency and Accountability

Transparency is paramount in building consumer trust and demonstrating a genuine commitment to sustainability. Brands should openly communicate their sustainable practices and material choices, providing detailed information about their supply chains and environmental impact throughout the product lifecycle. This transparency fosters accountability and allows consumers to make informed choices.

Promoting Sustainable Consumption

Brands have a responsibility to educate consumers about the importance of sustainable choices. This can be done through clear labeling, educational campaigns, and product design that prioritizes durability and repairability. Encouraging consumers to adopt a more sustainable lifestyle, through conscious consumption and responsible disposal, creates a ripple effect that benefits the environment and the brand's reputation. This fosters a more holistic approach to sustainability, moving beyond just product design to include consumer behaviour.