Innovative Solutions for Sustainable Textiles: New Breakthroughs

Natural Abundance and Versatility

Bio-based fibers, derived from renewable resources like plants and microorganisms, offer a compelling alternative to traditional petroleum-based materials. Their abundance in nature and the potential for sustainable production make them a critical component in the ongoing transition towards a more environmentally conscious textile industry. These materials hold immense promise for reducing our reliance on finite resources and minimizing the environmental footprint of fashion and other industries.

The versatility of bio-based fibers extends beyond their inherent sustainability. They can be processed and manipulated to create a wide array of textures, colors, and functionalities. This adaptability allows for the development of innovative products with specific properties, from lightweight fabrics for apparel to durable materials for construction.

Sustainable Production Practices

The production of bio-based fibers often relies on sustainable agricultural practices, which minimize environmental impact and promote biodiversity. These practices prioritize soil health, water conservation, and reduced pesticide use, contributing to a more harmonious relationship between agriculture and the environment. Careful consideration of the entire production cycle is paramount, ensuring that the environmental benefits extend throughout the supply chain.

Furthermore, the use of bio-based fibers can reduce greenhouse gas emissions compared to conventional synthetic fibers. This reduction directly contributes to mitigating climate change and promoting a more sustainable future.

Improved Material Properties

Bio-based fibers are increasingly demonstrating excellent performance properties, rivaling or even exceeding those of traditional materials. For example, some bio-based fibers exhibit exceptional strength and durability, making them suitable for a variety of applications. These advancements in material science are paving the way for innovative applications across numerous industries.

Innovations in processing techniques further enhance the properties of these materials. Advanced methods are continually being developed to improve the strength, softness, and water resistance of bio-based fibers, unlocking a wider range of possibilities for their use.

Economic Viability and Market Potential

The rising demand for sustainable materials is driving significant investment in the development and production of bio-based fibers. This investment is expected to fuel the growth of the bio-based materials market, creating new job opportunities and stimulating economic activity. This burgeoning market presents exciting prospects for entrepreneurs and investors alike.

Furthermore, the potential for cost reductions in the production of bio-based fibers, coupled with increasing consumer demand for sustainable products, promises to make these materials more economically attractive in the long run.

Technological Advancements in Processing

Technological advancements in processing bio-based fibers are crucial for optimizing their performance and reducing production costs. Continuous research and development are pushing the boundaries of material science, leading to more efficient and sustainable processing methods. This includes innovations in spinning, weaving, and finishing techniques. These technological breakthroughs are vital for bringing bio-based fibers to the forefront of the materials market.

Environmental Impact and Carbon Footprint

A significant advantage of bio-based fibers lies in their reduced carbon footprint compared to their petroleum-derived counterparts. By utilizing renewable resources, the lifecycle emissions of these materials are significantly lower. This environmental benefit is a key driver for their adoption across various industries, from fashion and textiles to packaging and construction.

Consumer Acceptance and Future Trends

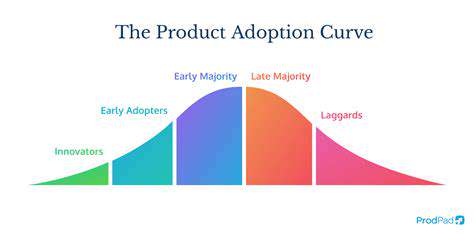

Consumer awareness and acceptance of sustainable materials are growing, and this trend is driving increased demand for bio-based fibers. As consumers become more conscious of their environmental impact, they are seeking out products that are environmentally friendly and ethical. This growing consumer demand is creating a positive feedback loop that will likely accelerate the adoption of bio-based fibers in the future.

The future likely holds further innovations in bio-based fiber production and application. Expect to see even more novel designs and functionalities as technology progresses and consumer demand continues to rise. This will lead to a more sustainable and environmentally friendly future for many industries.

Advanced Recycling Technologies: Turning Waste into Treasure

Innovative Approaches to Plastic Recycling

Advanced recycling technologies are pushing the boundaries of traditional methods, focusing on chemical processes to break down complex plastic polymers into their basic building blocks. This allows for the creation of new plastics with the same properties as virgin materials, significantly reducing reliance on fossil fuels for plastic production and lessening the environmental burden of plastic waste. These innovative approaches offer a pathway to a circular economy for plastics, where waste is transformed into valuable resources rather than accumulating in landfills or polluting our environment.

Chemical Recycling: A Deep Dive

Chemical recycling, a key component of advanced recycling, involves using chemical processes to break down plastic waste into its constituent monomers. These monomers can then be used to create new plastics, effectively transforming waste into raw materials for the production of virgin-quality plastics. This process holds significant promise for addressing the global plastic waste crisis, providing a pathway to a more sustainable future for plastic materials.

This approach differs significantly from mechanical recycling, which often struggles with the diverse range of plastics and the degradation of the recycled material. Chemical recycling offers a more versatile solution, potentially handling a wider variety of plastic types and maintaining the quality of the recycled product.

Bio-Based Plastics and Recycling Synergies

The development of bio-based plastics, derived from renewable resources like plants, offers a fascinating synergy with advanced recycling. These materials can be designed to be more easily broken down and recycled through chemical processes, creating a closed-loop system where organic waste is transformed into valuable resources. This approach not only reduces reliance on fossil fuels but also integrates biological processes into the recycling pipeline, offering a potentially more sustainable approach to plastic production and consumption.

Enhanced Material Recovery through Advanced Sorting

Advanced sorting technologies are crucial in the success of advanced recycling. These technologies use sophisticated techniques like optical sorting, spectroscopy, and density separation to identify and separate different types of plastic waste. This precise sorting allows for the efficient processing of plastic waste by ensuring that only suitable material is subjected to advanced recycling processes, thereby maximizing the yield and quality of the recovered resources. Accurate sorting is essential for the economic viability and environmental effectiveness of advanced recycling programs.

Economic Incentives and Policy Support

The widespread adoption of advanced recycling technologies requires significant investment and policy support. Government incentives, such as tax credits or subsidies for advanced recycling facilities, can encourage businesses to adopt these technologies and help make them financially viable. Policies that promote the collection and sorting of plastic waste and support research and development in this area are critical in driving progress towards a more sustainable plastic future. Ultimately, a holistic approach involving both private and public sectors is needed to achieve widespread implementation of these technologies.

The Future of Waste Management: A Sustainable Perspective

Advanced recycling technologies represent a crucial step towards a more sustainable waste management system. By transforming waste into valuable resources, these technologies can significantly reduce reliance on landfills and incineration, lowering the environmental footprint of plastic production and consumption. The development of advanced recycling methods is essential for mitigating the global plastic waste crisis, and continued innovation and investment will be key to ensuring a sustainable future for our planet.

Sustainable Dyeing and Finishing Processes: Minimizing Chemical Impact

Exploring Eco-Friendly Alternatives

Sustainable dyeing and finishing processes are crucial for minimizing the environmental impact of textile manufacturing. Traditional methods often rely heavily on synthetic chemicals, leading to significant water pollution and potential health risks. This necessitates a shift towards eco-friendly alternatives, such as natural dyes derived from plants, minerals, and insects. These natural sources offer vibrant colors and can be more environmentally benign compared to synthetic counterparts, reducing the reliance on harmful chemicals and promoting a circular economy in the textile industry.

Innovative approaches to dyeing and finishing involve exploring plant-based extracts, which can provide a wide range of colors and have lower environmental footprints compared to conventional chemical dyes. Researchers are actively investigating sustainable methods for extracting and processing these natural pigments, aiming to optimize their performance and efficiency while minimizing waste generation. Furthermore, the development of bio-based polymers and finishes offers a promising avenue for replacing petrochemical-derived materials, further reducing the environmental impact of the textile lifecycle.

Optimizing Wastewater Treatment and Recycling

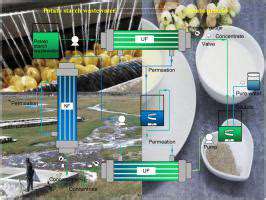

A critical component of sustainable dyeing and finishing is the effective management of wastewater. Traditional dyeing processes often discharge heavily polluted wastewater into water bodies, contaminating ecosystems and posing significant threats to aquatic life. Innovative solutions, such as advanced wastewater treatment technologies, are essential for removing harmful dyes and chemicals before releasing the treated water. This includes implementing membrane filtration systems, activated carbon adsorption, and biological treatment processes to achieve higher levels of purification and reduce the environmental burden.

Furthermore, the development of closed-loop systems that recycle wastewater and recovered materials is paramount. This approach minimizes the need for fresh water and reduces the overall consumption of resources. By implementing water recycling and reuse strategies, the textile industry can significantly decrease its water footprint and contribute to a more sustainable production model. Recycling and reuse of textile waste, including fibers and dyes, is another crucial component of this strategy, creating a closed-loop system to reduce the overall environmental impact.

Improving Energy Efficiency and Reducing Waste

Energy consumption is another significant factor in the environmental footprint of textile dyeing and finishing processes. Traditional methods often require substantial energy inputs for heating, cooling, and chemical reactions. Implementing energy-efficient technologies, such as solar energy and heat recovery systems, can significantly reduce the carbon footprint of these processes. Utilizing renewable energy sources and optimizing energy consumption in each step of the process is essential for creating a more sustainable textile production chain. This also involves exploring technologies that can reduce water consumption and chemical usage, aiming for a more resource-efficient process.

Minimizing waste generation throughout the entire process is equally important. From the selection of raw materials to the disposal of finished products, waste reduction strategies can contribute to a more sustainable approach. Implementing innovative design approaches that minimize material usage and maximize material recovery can create a more circular economy. This includes adopting greener solvents and reducing the use of hazardous chemicals in the dyeing and finishing stages. These improvements reduce the reliance on landfills and promote a more sustainable approach to textile production.

The Future of Circularity: Designing for Deconstruction and Reuse

Designing for Disassembly: The Importance of Deconstructible Design

Deconstructible design is crucial for a circular economy. It emphasizes the ability to easily separate components of a product at the end of its useful life. This allows for the recovery of valuable materials, reducing waste and minimizing the environmental impact of manufacturing new products. By incorporating design principles that facilitate disassembly, manufacturers can significantly contribute to the circularity of their products, fostering a more sustainable future.

This approach goes beyond simply using recyclable materials. It involves a proactive design process where the entire product lifecycle is considered, from initial creation to eventual dismantling. Careful planning and material selection are essential in making a product easily deconstructible, enabling maximum material recovery and minimizing the use of new resources.

Material Selection and Sourcing: Prioritizing Recyclability and Renewability

Choosing materials that are easily recyclable or can be repurposed is paramount. This often involves prioritizing renewable and recycled materials over virgin resources. Manufacturers can leverage innovative materials science to develop new materials that are more easily recyclable or can be broken down into their constituent parts without significant loss in quality or efficiency.

Furthermore, transparent and ethical sourcing practices are vital. Understanding the complete lifecycle of the materials used is crucial, ensuring that they are sourced responsibly and sustainably. This includes considering the environmental impact of the material extraction, transportation, and processing, as well as the labor conditions involved.

Advanced Manufacturing Techniques: Enabling Efficient Deconstruction

Modern manufacturing techniques play a critical role in supporting the circular economy. Innovative processes that enable the efficient disassembly of products are essential. This includes the use of standardized components, modular designs, and clearly marked labeling for each part, all contributing to easier disassembly and material recovery.

Utilizing advanced manufacturing methods, such as 3D printing, can also enable the creation of products with intricate designs that are still easily deconstructible. This opens the door for the creation of more complex products with enhanced functionality while maintaining a focus on the circularity of the materials and components.

The Role of Technology in Tracking and Managing Materials

Implementing technologies that track and manage materials throughout their lifecycle is essential for optimizing circularity. This includes digital platforms that can monitor the location and condition of products, predict their end-of-life, and guide their disassembly. Such systems provide valuable data for material recovery and recycling, helping to ensure that valuable resources are not lost.

Economic Incentives and Policy Support: Driving the Transition to Circularity

Government policies and financial incentives play a crucial role in encouraging the adoption of circular economy principles. Tax breaks, subsidies, and regulations can incentivize companies to design for disassembly and reuse. These incentives can drive innovation and encourage the development of more sustainable manufacturing practices.

Establishing clear policies and standards for material traceability and product labeling will be key to ensuring transparency and accountability throughout the supply chain. This ensures that consumers and businesses can make informed decisions about the products they use, promoting circularity across the entire system.

Consumer Education and Engagement: Fostering a Circular Mindset

Educating consumers about the benefits of circularity is essential for driving wider adoption. Promoting the use of durable products, understanding the importance of product lifespan, and encouraging responsible disposal practices will foster a circular mindset. Educating the public about the value of reusing and recycling materials empowers them to play an active role in a sustainable future.

Encouraging repair and reuse initiatives can also significantly contribute to the circularity of products. Promoting access to repair services and sharing platforms for used items can extend the lifespan of products and reduce the demand for new ones, creating a more sustainable consumption pattern.