The Role of Regenerative Fibers in Creating a Sustainable Future for Fashion

Understanding Regenerative Fibers

The Science Behind Fiber Regeneration

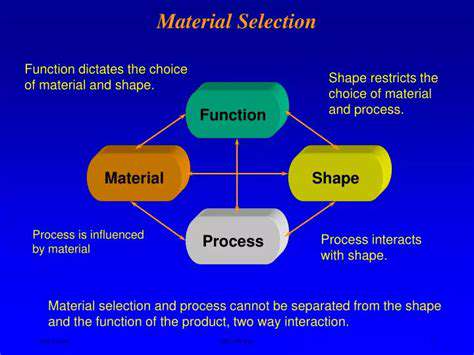

At the cutting edge of materials innovation, regenerative fibers represent a paradigm shift in how we create and utilize textiles. Unlike conventional production methods that deplete finite resources, these fibers employ advanced techniques to repurpose materials into superior forms. What makes this approach revolutionary is its closed-loop system - where waste becomes the foundation for new, high-performance materials. This methodology directly counters the environmental damage caused by traditional fiber manufacturing processes.

Distinctive Qualities That Set Regenerative Fibers Apart

Engineers have successfully developed regenerative fibers with exceptional characteristics that outperform their conventional counterparts. These materials demonstrate remarkable resistance to wear while maintaining flexibility, making them perfect for demanding applications. Perhaps most impressively, many variants decompose naturally after use, offering a practical solution to our global microplastic crisis. The adaptability of these fibers allows for precise customization to meet specific industry requirements, unlocking countless possibilities.

Innovative Material Sources Driving Change

The raw materials powering this revolution come from surprising places - agricultural waste that would otherwise be burned, discarded plastic pollution, and sustainably harvested plant matter. This transformative approach turns environmental liabilities into valuable assets, with each material source imparting unique benefits to the final product. From cellulose-based fibers that mimic natural fabrics to plastic-derived filaments with enhanced durability, the material diversity fuels innovation across multiple sectors.

The Ecological Transformation Through Fiber Innovation

Conserving Our Water Resources

Regenerative fiber production demonstrates remarkable water efficiency compared to conventional methods. Traditional cotton cultivation, for instance, consumes approximately 2,700 liters of water per t-shirt - a staggering amount that regenerative processes slash dramatically. This conservation is particularly vital in drought-prone regions where every liter counts, helping preserve aquatic ecosystems and community water supplies.

Nature's Recycling System at Work

The biodegradable nature of many regenerative fibers creates a harmonious cycle with the environment. When disposed of properly, these materials decompose completely, enriching soil rather than polluting it. This stands in stark contrast to synthetic fibers that may persist in landfills for centuries. Modern composting facilities can process certain regenerative fibers in as little as 90 days, effectively closing the loop on textile waste.

Fighting Climate Change Through Carbon Capture

Plant-based regenerative fibers act as carbon vaults, trapping atmospheric CO2 throughout their lifecycle. This natural sequestration process, combined with reduced manufacturing emissions, makes these fibers powerful climate allies. Some agricultural sources used in fiber production can capture up to 3 tons of CO2 per acre annually, making textile production part of the climate solution rather than the problem.

Practical Applications Across Industries

The versatility of regenerative fibers enables groundbreaking applications:

- High-performance sportswear that combines durability with sustainability

- Medical textiles with enhanced biocompatibility

- Automotive interiors that reduce vehicle weight while maintaining safety

- Construction materials that strengthen buildings while lowering embodied carbon

Overcoming Challenges for Widespread Implementation

Scaling Production Responsibly

While the technology shows immense promise, scaling production while maintaining quality standards presents logistical hurdles. Industry leaders are investing heavily in advanced manufacturing facilities that can meet growing demand without compromising environmental benefits. Pilot programs across Europe and Asia are demonstrating that large-scale production is achievable with proper planning.

Cost Considerations and Market Adoption

The premium pricing of early regenerative fiber products has slowed mainstream acceptance. However, as production scales and technology improves, prices are projected to drop 30-40% within five years, making these materials competitive with conventional options. Forward-thinking brands are already incorporating regenerative fibers into their product lines, creating market pull that will drive further innovation.

Standardization and Certification

Establishing clear industry standards remains crucial for building consumer trust. Organizations like the Global Organic Textile Standard (GOTS) are developing specific criteria for regenerative fibers. Third-party certifications will help consumers identify genuinely sustainable options amidst growing greenwashing concerns in the textile industry.

The Road Ahead: Consumer Engagement and Education

Bridging the Knowledge Gap

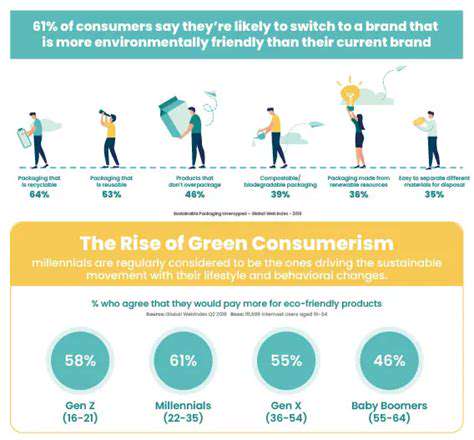

Public awareness campaigns play a pivotal role in driving adoption of regenerative fiber products. Clear labeling and transparent supply chain information empower consumers to make informed choices. Educational initiatives that highlight the environmental benefits compared to conventional materials can shift purchasing behaviors over time.

Collaborative Industry Efforts

Leading fashion brands and textile manufacturers are forming coalitions to accelerate the transition to regenerative materials. These partnerships pool research resources and share best practices, creating industry-wide momentum. Such cooperation is essential for overcoming technical challenges and establishing production benchmarks.

Policy Support and Incentives

Government initiatives can significantly boost the regenerative fiber market. Potential measures include:

- Tax credits for manufacturers adopting regenerative processes

- Research grants for universities and private labs

- Procurement policies favoring sustainable textiles

- Extended producer responsibility regulations

As the sector matures, these fibers could transform from niche alternatives to mainstream staples, fundamentally changing how we produce and consume textiles while addressing urgent environmental challenges.