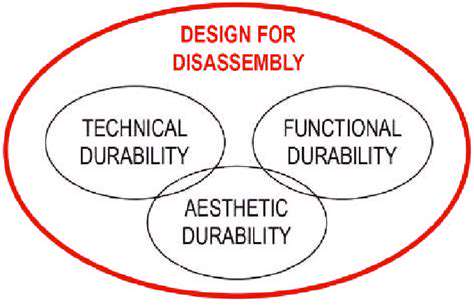

Designing for Disassembly: The Key to Circular Products: New Principles

The push for circularity in product design revolves around creating products that can be easily taken apart. This shifts focus from the old take-make-waste approach to a system where materials get reused repeatedly. When products are built with disassembly in mind, we can recover up to 90% of materials for new uses, drastically cutting down on waste. The key lies in understanding how products come apart - this knowledge lets us separate materials cleanly and efficiently.

Forward-thinking companies that design for disassembly from the start see multiple benefits. They reduce environmental harm while uncovering new revenue streams from reclaimed materials. What many don't realize is that designing for disassembly isn't just about being green - it's becoming a competitive necessity as resource costs rise and regulations tighten.

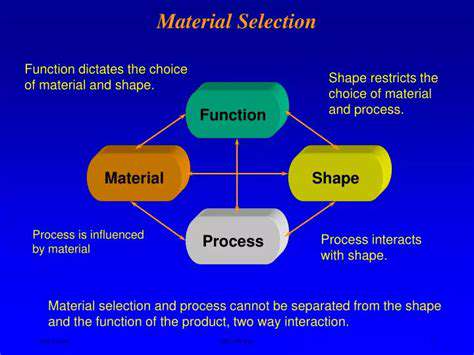

Material Selection and Component Integration

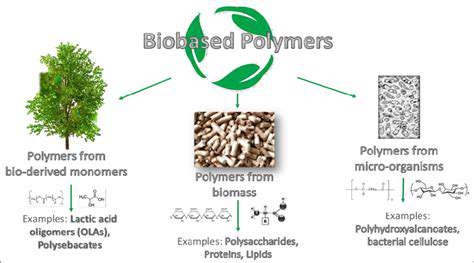

Choosing the right materials makes all the difference in disassembly. Designers need to pick materials that separate easily while maintaining product quality. This requires close teamwork between designers, scientists, and recycling experts throughout development. Using common parts and modular designs simplifies disassembly dramatically.

Material compatibility matters just as much as individual material choices. Designers must consider how materials interact during disassembly and whether local recycling facilities can handle them. Smart planning here prevents contamination and ensures materials flow smoothly into recycling systems.

Modular Design and Component Standardization

Modular design changes the game for circular products. By creating products in independent modules, companies can swap out or upgrade parts instead of replacing entire products. Standardized parts take this further by making components interchangeable across product lines. This approach has helped some manufacturers reduce production costs by 30% while cutting waste by half.

Process Optimization and Tooling

Efficient disassembly requires well-planned processes. Companies investing in specialized tools and clear dismantling instructions see faster turnaround and higher material recovery rates. Some are even automating disassembly lines for consistent results. The right tools make material separation safer and more thorough, maximizing what gets recycled.

Lifecycle Assessment and End-of-Life Planning

Comprehensive lifecycle analysis reveals a product's true environmental impact. Companies using LCA data have identified up to 40% improvement opportunities in their designs. Smart end-of-life planning includes take-back programs and partnerships with recyclers to keep materials circulating. These steps ensure products don't just disappear into landfills when their first life ends.

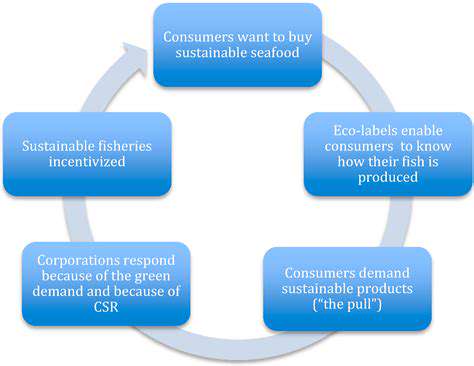

Collaboration and Industry Standards

Circular design succeeds through teamwork. When designers, manufacturers and recyclers align on standards, everyone benefits. Transparency about materials and construction helps recyclers process items efficiently. Consumer education completes the circle - when people understand how to participate, recycling rates can double. Together, we're building systems where waste becomes obsolete.

The Role of Technology in Facilitating Disassembly

The Importance of Design for Disassembly

Smart disassembly design solves multiple problems at once. Products that come apart easily save time and money while recovering more materials. Thoughtful design eliminates the need for special tools or training, making recycling accessible to more businesses. Some companies have cut disassembly time by 75% through better design, proving that small changes create big impacts.

Material Selection for Enhanced Disassembly

Material choices make or break disassembly efforts. Using compatible materials that separate cleanly prevents recycling headaches. Standard materials with established recycling streams ensure nothing goes to waste. The best designs consider how materials behave during disassembly to avoid contamination.

Modular Design Principles and Component Interconnection

Modular designs transform complex products into simple puzzles. Well-designed modules disconnect with basic tools, preserving components for reuse. Standard connections like clips and screws outperform permanent bonds when disassembly matters. Modular electronics, for example, have extended product lifespans by 300% in some cases.

Standardized Component Specifications

Standard parts revolutionize product maintenance and recycling. When components follow industry norms, they fit multiple products and recycling systems. This standardization simplifies everything from repairs to material recovery. Companies using standard parts report 40% fewer errors in disassembly operations.

Tooling and Equipment Considerations

Disassembly-friendly designs work with common tools. This eliminates the cost and complexity of specialty equipment. Some innovators even design products that disassemble themselves with simple mechanisms. Smart tool integration makes material recovery safer and more predictable.

Environmental Impact and Resource Recovery

Designing for disassembly turns waste into wealth. More efficient material recovery means less mining and manufacturing. Some automotive manufacturers now recover 95% of vehicle materials thanks to disassembly-focused design. Each ton of recycled materials can save up to 10 tons of CO2 emissions compared to virgin materials.

Economic Benefits of Facilitated Disassembly

The business case for disassembly grows stronger yearly. Faster disassembly slashes labor costs, while recovered materials generate new revenue. Some companies find the recycled materials from their products cover the cost of collection and processing. As resource prices fluctuate, disassembly design provides valuable insulation against supply chain risks.