The Benefits of Post Consumer Recycled Content in Apparel

Transparency has become non-negotiable for many shoppers. They want proof of ethical labor practices, verifiable sustainability claims, and clear information about materials. Smart brands now provide detailed supply chain maps and third-party certifications to meet this demand for accountability.

The Promise of Post-Consumer Recycled Content

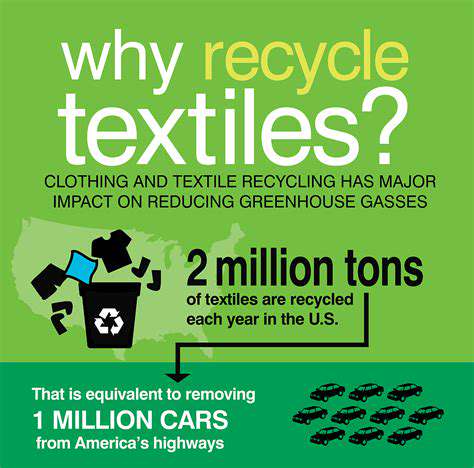

Recycled materials offer one of the most promising solutions to fashion's waste crisis. By giving new life to discarded textiles and plastics, manufacturers can dramatically reduce their environmental impact. This approach conserves water (recycled polyester uses 90% less water than virgin polyester), reduces energy consumption, and keeps waste out of landfills.

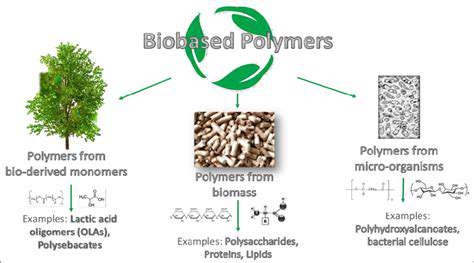

The technology behind textile recycling continues to advance rapidly. What began with simple shredding and re-spinning has evolved into sophisticated chemical processes that can break down blended fabrics and restore fibers to near-virgin quality. These innovations make recycled content increasingly viable for high-performance applications.

The Benefits of PCR in Apparel Production

Incorporating recycled materials affects every stage of production positively. Factories report lower energy bills when using recycled inputs, while communities benefit from reduced pollution. The water savings alone make a compelling case - producing one cotton t-shirt from virgin materials consumes about 700 gallons of water, versus minimal amounts for recycled alternatives.

Economic Advantages of Recycling

While sustainability drives much of the recycled materials movement, the economic benefits are equally significant. Recycled polyester currently costs about 15-20% less than virgin polyester, with similar savings across other materials. These cost advantages grow as recycling infrastructure improves and scales up.

Consumer Acceptance and Market Growth

Market research shows steady growth in demand for sustainable apparel, particularly among younger demographics. Over 60% of millennials report actively seeking out eco-friendly clothing options, and they're willing to pay a premium for verified sustainable products. This shift creates exciting opportunities for brands that authentically embrace circular principles.

Challenges and Future Outlook

Despite progress, significant hurdles remain. Collection systems for used textiles need massive expansion, and recycling technology must continue advancing to handle complex fabric blends. Perhaps most crucially, consumer education about proper clothing disposal and recycling remains inadequate in many markets.

The coming years will likely see increased government regulation of textile waste, potentially including extended producer responsibility laws. Such policies could accelerate industry adoption of recycled materials by making brands financially responsible for their products' end-of-life impacts.

Economic Advantages and Cost-Effectiveness

Reduced Material Costs

Processing recycled materials requires significantly less energy than producing virgin materials - up to 50% less in some cases. These energy savings translate directly to lower production costs that manufacturers can pass along to consumers. The stability of recycled material prices also protects businesses from the volatile commodities market that affects virgin materials.

Environmental Sustainability and Reduced Carbon Footprint

The carbon reduction potential of recycled materials is staggering. Producing recycled polyester generates 75% less CO2 than virgin polyester production. These savings come not just from reduced energy use but also from eliminating the need for petroleum extraction and initial processing.

Increased Efficiency in Production Processes

Modern recycling facilities can now produce materials with consistent quality that integrates seamlessly with existing manufacturing equipment. This reliability reduces downtime and waste during production while maintaining product quality standards.

Enhanced Product Durability and Longevity

Contrary to common assumptions, recycled materials often match or exceed the durability of virgin materials. Recycled polyester fibers, for example, demonstrate excellent tensile strength and color retention after multiple washes. This durability extends product lifespans, reducing replacement costs for consumers.

Improved Supply Chain Resilience

By diversifying material sources to include recycled inputs, manufacturers reduce their vulnerability to supply chain disruptions. This became particularly evident during recent global shipping crises, when brands relying on recycled local materials maintained more stable operations than those dependent on overseas virgin material suppliers.

Potential for New Market Opportunities

The recycled materials sector has spawned entirely new business models, from textile collection services to advanced sorting facilities. Forward-thinking companies are finding profitable niches in this growing ecosystem while contributing to environmental solutions.

Improved Product Performance and Durability

Enhanced Durability Through Recycled Materials

Modern recycling processes can actually improve certain material properties. For example, some recycled plastics demonstrate higher impact resistance than their virgin counterparts due to molecular changes during recycling. These characteristics make recycled materials ideal for products requiring exceptional durability.

Improved Product Performance Through Material Consistency

Advanced sorting and processing technologies now yield recycled materials with remarkably consistent properties. This consistency enables manufacturers to predict performance more accurately and reduce product defects or failures.

Cost-Effectiveness and Reduced Environmental Impact

The dual benefits of lower costs and smaller environmental footprint make recycled materials increasingly attractive across industries. As production scales up, these advantages will only grow more pronounced.

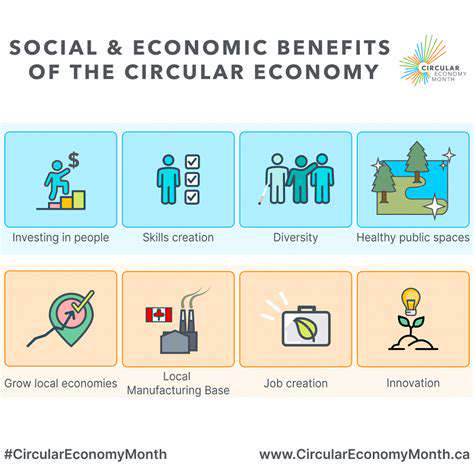

Sustainability and Social Responsibility

Using recycled materials demonstrates concrete environmental commitment that resonates strongly with today's consumers. Brands that authentically embrace sustainability often see improved customer loyalty and brand perception as a result.

Increased Product Life Cycle by Reduced Waste

The circular economy principles behind recycled materials fundamentally change how we view product lifecycles. Instead of a straight line from factory to landfill, materials can now complete multiple useful cycles before final retirement.

Material Versatility and Adaptability in Design

Designers are discovering creative new applications for recycled materials, from athletic wear to high fashion. This versatility proves that sustainability doesn't require sacrificing style or performance.

The Future of Sustainable Fashion with Recycled Content

Exploring the Environmental Impact

The potential environmental benefits of widespread recycled material adoption are enormous. If the fashion industry replaced just half of virgin polyester with recycled alternatives, it could reduce global CO2 emissions by millions of tons annually while saving billions of gallons of water.

Economic Advantages of Recycled Fashion

As recycling infrastructure expands, the economic case for sustainable fashion strengthens. Economies of scale are already making recycled materials more cost-competitive, while consumer demand creates premium pricing opportunities for truly sustainable brands.

Innovations in Recycled Material Sourcing and Processing

Emerging technologies promise to revolutionize textile recycling. Enzymatic breakdown of fabrics, advanced fiber-to-fiber recycling systems, and AI-powered sorting machines all point toward a future where clothing recycling becomes as routine as paper or glass recycling is today.

Consumer Engagement and Ethical Considerations

Authentic sustainability requires transparency at every level. Brands must provide verifiable information about their supply chains while ensuring fair wages and safe conditions for all workers. Consumers increasingly recognize that true sustainability encompasses both environmental and social responsibility.