The Human Face of Fast Fashion: Understanding Exploitation

Unraveling the Threads: The Human Cost Behind Our Garments

Behind Factory Walls: The Reality of Garment Labor

Hidden within supply chains are workplaces where basic human dignity is often compromised. Workers face grueling 14-hour shifts in factories where emergency exits are frequently locked and ventilation is inadequate. These conditions don't merely violate labor standards - they systematically erode workers' physical and mental health over time. In nations where job alternatives are scarce, employees endure these hazards simply to put food on their families' tables.

The Ripple Effects of Exploitative Employment

Chronic back pain from standing 16 hours daily is just the visible tip of this iceberg. Many workers develop permanent vision damage from poor lighting and repetitive close work. Their meager wages - often below $3 per day - force impossible choices between medicine for a sick child or school fees for their eldest. This economic stranglehold perpetuates intergenerational poverty, creating a workforce perpetually vulnerable to exploitation.

Global Supply Chains and the Race to the Bottom

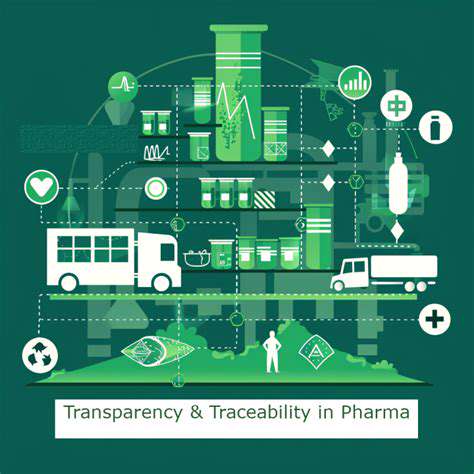

Transnational corporations have perfected the art of distancing themselves from production realities. By subcontracting through multiple intermediaries, they maintain plausible deniability about workplace conditions. The current system incentivizes this opacity - each 10% reduction in labor costs can mean millions in additional profit for shareholders. Consumers see only the final price tag, not the human suffering woven into each stitch.

Conscientious Consumerism in Practice

Ethical consumption requires more than good intentions - it demands concrete action. When shoppers prioritize factory transparency over bargain prices, they create market pressure for systemic change. Apps like Good On You and certification programs (Fair Trade, B-Corp) help identify brands that audit their supply chains. Supporting these companies builds economic momentum toward humane manufacturing.

International Oversight and Its Limitations

While the ILO sets important benchmarks, enforcement remains inconsistent across borders. Some nations treat these standards as suggestions rather than requirements. Recent innovations like blockchain supply chain tracking offer promise for greater accountability, but widespread adoption faces resistance from cost-conscious manufacturers. Worker-led unions remain the most effective local enforcement mechanism.

Building Sustainable Alternatives

Transformative change requires addressing root causes. Living wage requirements in trade agreements could prevent labor arbitrage. Consumer education campaigns must highlight how $5 t-shirts are mathematically impossible without exploitation. Worker cooperatives demonstrate that ethical production is commercially viable - their growth should be incentivized through trade policy and investment.

Mindful Wardrobes: Reimagining Our Relationship with Clothing

The Ecological Toll of Disposable Fashion

Today's apparel industry produces over 100 billion garments annually - enough for 14 new items per person worldwide. This volume strains planetary boundaries, from the 2,700 liters of water needed for one cotton shirt to the microplastic pollution from synthetic fibers. Textile dyeing alone ranks as the world's second-largest water polluter, contaminating rivers that entire communities depend upon. The solution lies not in better recycling, but in radical reduction of throughput.

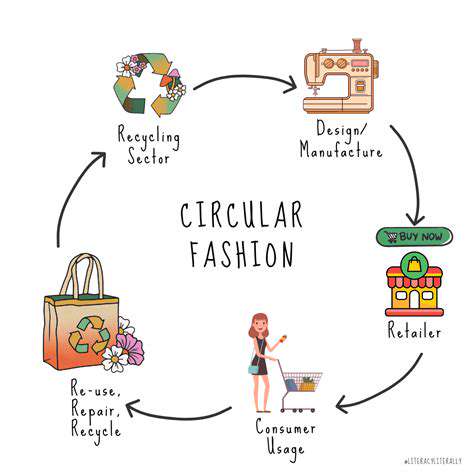

Landfill realities are equally sobering. A garbage truck's worth of clothing gets buried or burned every second globally. Natural fibers release methane as they decompose, while synthetics may persist for centuries. Secondhand markets absorb less than 20% of discarded clothing, revealing the urgent need for extended producer responsibility programs.

The People Behind the Price Tags

That $9.99 dress exacts a hidden human toll. In Dhaka factories, workers collapsing from heat exhaustion is disturbingly common. Safety shortcuts claimed 1,138 lives in the Rana Plaza collapse - a preventable tragedy that revealed systemic negligence. These aren't isolated incidents, but symptoms of an industry that treats people as disposable as the garments they produce. Ethical brands prove living wages don't significantly impact retail prices when executive bonuses are moderated.

Escaping the Consumption Trap

Social media accelerates fashion turnover while eroding self-esteem. The average young adult now considers clothing old after just 7-8 wears. This manufactured dissatisfaction drives unnecessary purchases - 40% of bought clothes are never actually worn. Breaking this cycle requires recognizing how marketing manipulates our insecurities for profit.

Practical Steps Toward Change

Building an ethical wardrobe starts with wearing items until they're truly worn out - the average garment lifespan has decreased by 36% since 2000. Platforms like The True Cost help consumers visualize their impact, while clothing swaps and rental services offer sustainable alternatives. Most powerful is simply buying less - each 10% reduction in purchases cuts your fashion footprint proportionally.

Redefining Personal Style

Authentic self-expression flourishes when freed from seasonal trends. A minimalist capsule wardrobe of 30-40 versatile pieces typically satisfies most needs. Developing personal style is paradoxically about removing choices - focusing on what truly resonates rather than reacting to marketing. This intentional approach fosters deeper satisfaction with fewer items.

The Art of Clothing Longevity

Quality construction matters - a well-made seam can last decades. Simple skills like darning socks or replacing buttons multiply a garment's lifespan. Japanese sashiko visible mending has become a global movement, transforming repairs into decorative features. These practices reconnect us with our belongings, fostering the care that disposable fashion discourages.