The Power of Data: New Insights for Circular Fashion

The Rise of Data-Driven Design

The fashion landscape is experiencing a seismic shift as data becomes its new lifeblood. Unlike traditional methods that relied on intuition, today's designers harness powerful datasets to decode consumer desires with surgical precision. This analytical approach doesn't just influence designs—it completely rewrites the creative process, blending artistry with empirical evidence. The result? Collections that resonate more deeply because they're built on what people truly want, not just what designers imagine they might like.

Personalized Experiences and Tailored Products

Modern shoppers don't just want options—they crave recognition. Advanced data analytics now allow brands to craft experiences so individualized they feel psychic. We're seeing algorithms that don't just track past purchases but predict future style evolutions, creating a shopping experience that feels less transactional and more like a style partnership. This shift represents nothing less than the death of one-size-fits-all fashion, replaced by a new era of hyper-relevant personal curation.

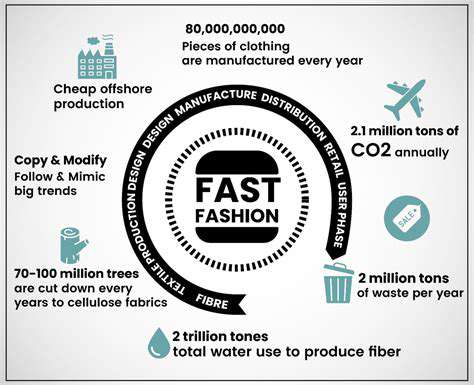

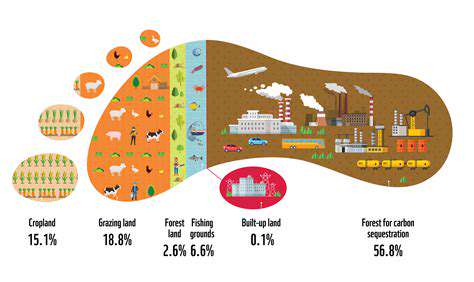

Optimized Supply Chains and Manufacturing

The hidden backbone of fashion is undergoing its own data transformation. Where once factories operated with educated guesses, now every thread and shipment leaves a digital footprint. Real-time tracking systems have turned opaque supply chains into transparent, living systems that constantly self-optimize. The environmental impact is profound—less waste, smarter resource use, and production cycles that adapt dynamically to actual demand rather than projections.

Enhanced Marketing and Sales Strategies

Gone are the days of spray-and-pray advertising. Today's fashion marketers wield data like master tailors, crafting messages that fit each customer segment perfectly. This precision targeting doesn't just boost sales—it creates meaningful connections by showing customers exactly what they want to see, exactly when they're ready to see it. The result is marketing that feels less like interruption and more like valuable service.

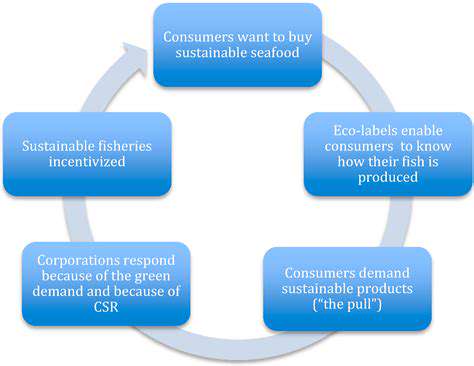

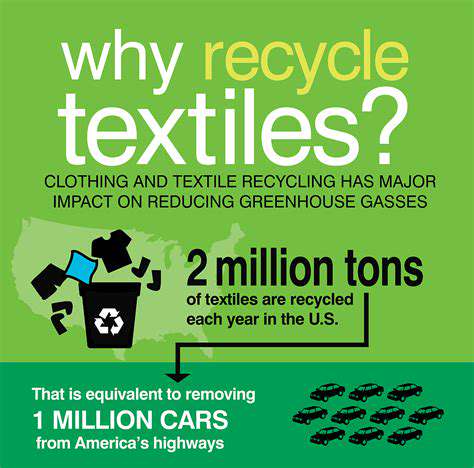

Sustainable Practices and Ethical Production

Data is proving to be fashion's unlikely environmental hero. By quantifying the true cost of materials and processes, brands can no longer hide behind vague sustainability claims. Every decision now comes with hard numbers—carbon footprints measured down to the gram, water usage tracked by the liter, and labor conditions documented in real-time. This level of accountability is forcing the industry to clean up its act in ways activists could only dream of a decade ago.

Improved Customer Relationship Management

The customer-brand relationship has evolved from transactional to symbiotic, with data serving as the connective tissue. Modern CRM systems don't just record purchases—they build psychological profiles, predicting needs before customers articulate them. This creates a virtuous cycle where better understanding leads to better service, which in turn generates deeper loyalty and more valuable data. The human touch hasn't disappeared—it's been enhanced by data's ability to reveal what customers truly value.

The Future of Fashion Technology

We're witnessing not just evolution but revolution—data is rewriting fashion's DNA. The most forward-thinking brands aren't just using data—they're building organizations where data fluency is as fundamental as design skills or business acumen. Tomorrow's successful fashion houses will be those that treat data not as a tool but as a foundational element, as essential as fabric or thread. The result will be an industry that's more responsive, more responsible, and more attuned to real human needs than ever before.

Optimizing Supply Chains for Enhanced Transparency and Efficiency

Data-Driven Visibility: Unveiling Supply Chain Insights

Modern analytics tools are peeling back the curtain on supply chain operations, revealing what was once invisible. Every material shipment, production delay, and transportation hiccup now generates actionable intelligence. This new transparency does more than identify problems—it creates opportunities to reinvent processes from the ground up. The most innovative companies are using these insights not just to tweak existing systems, but to completely reimagine how goods flow from concept to customer.

What makes this revolution remarkable is its predictive capability. Advanced systems don't just report on current status—they forecast potential disruptions weeks or months in advance. This foresight transforms supply chain management from reactive firefighting to strategic chess, where moves are planned several steps ahead.

Predictive Modeling for Proactive Management

The crystal ball of fashion has arrived—not through magic but mathematics. Today's predictive models digest everything from weather patterns to social media trends, outputting remarkably accurate forecasts. These aren't simple extrapolations, but complex simulations that account for dozens of variables most businesses wouldn't think to consider. The brands mastering this approach don't just survive market fluctuations—they anticipate and capitalize on them.

Inventory management has particularly benefited from this revolution. Where once warehouses alternated between overstuffed and empty, smart algorithms now maintain perfect equilibrium. The financial impact is staggering—reduced capital tied up in stock, fewer s from overproduction, and near-elimination of stockouts that frustrate customers and damage brands.

Streamlining Processes with Automation

Automation in fashion supply chains isn't about replacing humans—it's about augmenting their capabilities. Intelligent systems handle the repetitive while freeing human talent for creative problem-solving and strategic thinking. The results speak for themselves: fewer errors, faster turnaround times, and employees who can focus on adding real value rather than fighting fires caused by manual processes.

Enhanced Supplier Relationships Through Collaboration

The data revolution has turned supplier relationships from adversarial negotiations into true partnerships. Shared dashboards create alignment, with both parties working from the same real-time information. This transparency builds trust while eliminating the blame game—when issues arise, both sides see them simultaneously and collaborate on solutions. The result is a supply network that behaves more like a single, well-oiled machine than a collection of competing interests.

Measuring and Monitoring Key Performance Indicators (KPIs)

The old adage you can't manage what you don't measure has never been more relevant. Modern KPI tracking goes far beyond basic metrics, drilling into dozens of performance indicators across the entire value chain. What makes today's approach different is its dynamism—KPIs evolve as business needs change, and alerts trigger automatically when thresholds are breached. This creates organizations that don't just report on performance, but continuously self-optimize in pursuit of excellence.

The most sophisticated operations have moved beyond lagging indicators to predictive metrics. Instead of measuring past performance, they track leading indicators that forecast future outcomes. This allows for course corrections before problems materialize, maintaining smooth operations even in volatile conditions.