The Role of Digital Twins in Circular Fashion: Virtualizing the Loop

The Growing Need for Sustainable Practices in Fashion

The Environmental Impact of Fast Fashion

Few industries leave as heavy a mark on our planet as fashion. Each year, textile production generates more greenhouse gases than all international flights and maritime shipping combined. The rise of fast fashion has accelerated this environmental crisis, with brands churning out disposable clothing at unprecedented rates. These garments, often made from synthetic fibers derived from petroleum, can take centuries to decompose in landfills.

The true cost of a $5 t-shirt becomes apparent when we examine its journey from cotton field to landfill. Conventional cotton farming consumes massive amounts of water and pesticides, while textile dyeing ranks as the world's second-largest polluter of clean water. The shipping of these goods across continents further compounds their carbon footprint. Clearly, we need revolutionary approaches to break this destructive cycle.

The Ethical Considerations in Fashion Production

Behind every cheap garment lies a human story that often goes untold. In Bangladesh, garment workers earning less than $100 per month risk their lives in factories with poor safety standards. The 2013 Rana Plaza collapse, which killed over 1,100 workers, exposed the deadly consequences of unchecked industry practices. Yet seven years later, many brands still struggle to monitor their extended supply chains effectively.

Modern slavery persists in fashion's shadow economy. From Uzbek cotton fields to Chinese textile mills, forced labor continues to taint global supply chains. Consumers are waking up to these realities, with 66% of global shoppers now willing to pay more for sustainable brands. This shift in consciousness presents both a challenge and opportunity for the industry.

The Role of Digital Twins in Optimizing Production Processes

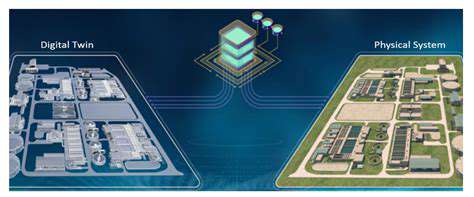

Imagine being able to test a new manufacturing process without wasting a single thread. Digital twin technology makes this possible by creating virtual replicas of entire production systems. Brands like Adidas are already using these simulations to reduce material waste by up to 30% in their prototyping phases. The technology allows designers to visualize how different fabric choices will drape and wear before cutting any physical material.

These virtual models can also predict how small changes - like adjusting stitching patterns or material blends - might affect a garment's durability and recyclability. By running thousands of digital simulations, companies can identify the most sustainable production methods before committing resources. This represents a quantum leap from the traditional trial-and-error approach that generates so much waste.

The Potential of Digital Twins for Circular Fashion

The fashion industry's holy grail - a truly circular production model - may finally be within reach through digital twin technology. By embedding smart tags in garments, brands can track items throughout their lifecycle. This data feeds back into the digital twin, creating a continuous improvement loop. Patagonia's Worn Wear program demonstrates how this works in practice, with returned items being repaired, resold, or recycled based on their digital profiles.

Empowering Design and Product Lifecycle Management

Understanding the Design Process

Great design begins with deep observation. The most successful fashion houses employ anthropologists to study how people actually wear and care for their clothes. This research informs every stage of development, from initial sketches to final production. Japanese designer Issey Miyake famously spent three years perfecting a single pleating technique that revolutionized sustainable garment care. Such dedication to process separates timeless design from temporary trends.

Prioritizing User Needs

Consider the humble hoodie - a garment that evolved from workwear to cultural icon because it answered real human needs. Today's most innovative designers use body scanning technology to create clothing that moves with the wearer. Brands like Ministry of Supply use NASA-inspired temperature regulation technology to make clothes that adapt to the wearer's environment. When form follows function this precisely, sustainability becomes inherent rather than an afterthought.

Innovative Product Development

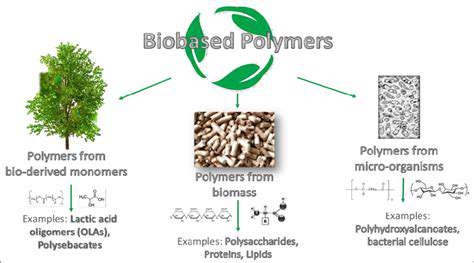

The most exciting innovations often come from cross-pollination. Adidas's partnership with Parley for the Oceans transforms ocean plastic into high-performance sportswear. Dutch designers are growing mushroom-based leather alternatives in labs. These breakthroughs demonstrate how constraints can spark creativity. As Stella McCartney proves season after season, ethical fashion need not compromise on style or performance.

Sustainable Product Lifecycle

Forward-thinking brands are reimagining ownership models to extend product lifecycles. Eileen Fisher's take-back program refreshes and resells used garments, while Mud Jeans leases denim that customers can return for recycling. These models flip the traditional sales approach, incentivizing durability over disposability. When companies retain responsibility for their products beyond the point of sale, sustainability becomes good business.

Iterative Testing and Refinement

The tech world's agile methodology is transforming fashion development. Brands like Zara have long used rapid prototyping to test designs in select markets before full production. Now, digital tools allow for even faster iteration. 3D design platforms like Browzwear enable instantaneous adjustments based on real-time feedback, eliminating the need for countless physical samples.

Market Analysis and Competitor Insights

The most successful sustainable brands don't just follow trends - they anticipate cultural shifts. When Reformation launched in 2009, fast fashion still dominated. By focusing on transparent sourcing and carbon-neutral production, they carved out a lucrative niche that major brands now scramble to emulate. True market leadership comes from spotting the gaps between what exists and what conscientious consumers actually want.