Policy and Legislation: Driving Global Circular Fashion Adoption

Extended Producer Responsibility (EPR) is a valuable environmental policy instrument that holds producers accountable for the environmental impacts of their products throughout their entire lifecycle. This includes the design, production, use, and end-of-life management of products, from cradle to grave. By shifting responsibility from consumers and governments to producers, EPR aims to promote more sustainable consumption and production patterns.

EPR encourages producers to internalize environmental costs, leading to more environmentally friendly product designs and manufacturing processes. This ultimately results in reduced waste generation, minimized pollution, and enhanced resource efficiency.

Key Principles of EPR

The core principles of EPR revolve around the concept of producer responsibility. Producers are incentivized to design for recyclability, reuse, and minimal environmental impact. This includes factors such as material selection, product lifespan, and end-of-life management solutions.

Economic Incentives in EPR

EPR often utilizes economic instruments to encourage responsible behaviour. These instruments can include taxes on environmentally harmful products, subsidies for eco-friendly alternatives, and deposit-refund schemes. These economic incentives aim to reflect the true cost of environmental damage associated with products.

Implementing these incentives can significantly influence producer behaviour, encouraging them to invest in cleaner technologies and more sustainable product designs.

Environmental Benefits of EPR

The environmental benefits of EPR are substantial. It reduces waste generation by promoting recycling and reuse, minimizing pollution from manufacturing and disposal processes, and conserving natural resources. These reductions in environmental impact contribute significantly to a healthier planet.

Furthermore, EPR fosters innovation in eco-friendly materials and technologies, ultimately leading to a more sustainable economy.

Challenges in Implementing EPR

Implementing EPR programs can present several challenges. These include the need for robust infrastructure for recycling and waste management, the complexity of coordinating producer responsibilities across different sectors, and the potential for administrative burdens. These challenges require careful planning and consideration during the implementation phase.

Case Studies and Success Stories

Numerous countries and regions have successfully implemented EPR programs, demonstrating the viability and effectiveness of this approach. These case studies offer valuable insights into best practices, lessons learned, and potential future directions for the development and implementation of EPR systems.

Future Trends and Developments

The future of EPR is likely to see a continued evolution, driven by increasing consumer awareness of environmental issues and stricter regulatory frameworks. Technological advancements, such as improved recycling technologies and advanced materials science, will play a vital role in enhancing the effectiveness of EPR programs.

Furthermore, the integration of EPR with other sustainable policies and practices will become increasingly important for achieving broader environmental goals.

Enforcing Transparency and Traceability in Supply Chains

Enhancing Visibility Through Technology

Implementing robust tracking technologies, such as blockchain and radio-frequency identification (RFID), allows for real-time visibility into every stage of the supply chain. This granular level of detail empowers businesses to monitor product movement, identify potential bottlenecks, and ensure compliance with regulations. Such technology investments can significantly reduce risks and improve operational efficiency, ultimately leading to greater transparency and trust among stakeholders.

Establishing Clear Product Origin Tracing

Establishing standardized procedures for documenting product origins is crucial. This involves recording information about raw materials, manufacturing processes, and distribution points. Detailed records are essential for identifying the source of products in case of recalls or quality issues. This comprehensive tracking system not only protects consumers but also enhances the reputation and trustworthiness of businesses involved in the supply chain.

Mandating Supplier Certification and Audits

Implementing mandatory supplier certifications and audits can significantly improve supply chain transparency. Certifications can ensure suppliers adhere to ethical labor practices, environmental standards, and safety regulations. Regular audits help verify compliance and identify areas for improvement. By holding suppliers accountable, companies can proactively mitigate risks associated with unethical or unsustainable practices throughout the supply chain.

Promoting Data Sharing and Collaboration

Encouraging data sharing among stakeholders in the supply chain is paramount for achieving full transparency. This includes fostering collaboration between producers, distributors, retailers, and consumers. Open communication channels, facilitated by technological platforms, can improve information flow, enabling stakeholders to make informed decisions. Sharing data can also lead to more efficient resource allocation and better risk management across the entire supply chain.

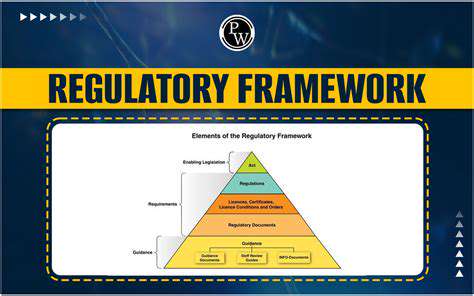

Strengthening Regulatory Frameworks

Governments play a vital role in promoting transparency by establishing clear and comprehensive regulations. These regulations should mandate the disclosure of key information, such as sourcing details and environmental impact assessments. Stronger regulations can effectively deter fraudulent activities and ensure ethical practices are upheld throughout the supply chain. Consistent enforcement of these regulations is critical for their effectiveness.

Fostering Consumer Awareness and Engagement

Raising consumer awareness about the importance of transparency in supply chains is essential. Educating consumers about their rights and the impact of their purchasing decisions can encourage more responsible consumption. Platforms and initiatives that provide consumers with access to detailed product information and supplier details can empower them to make informed choices that align with their values. This engagement drives demand for transparency and accountability throughout the supply chain.

Implementing Effective Enforcement Mechanisms

To ensure compliance with transparency and traceability regulations, effective enforcement mechanisms are needed. This includes establishing clear penalties for non-compliance and providing channels for reporting suspected violations. These mechanisms must be accessible and transparent to encourage the reporting of potential issues. Robust enforcement is critical for ensuring the long-term success and sustainability of transparency initiatives in supply chains.