Transparency Tools for Ethical Fashion Shoppers: Making Informed Decisions

Understanding the Complexities of Fashion Supply Chains

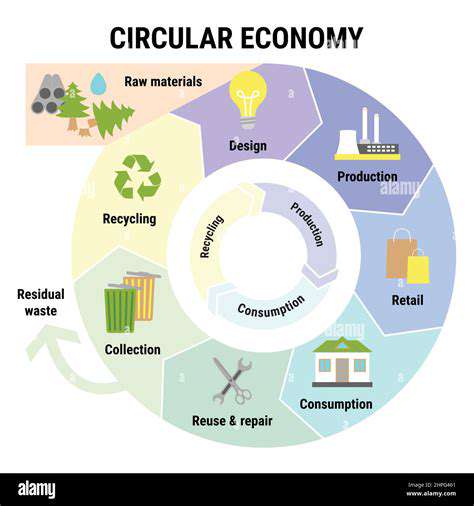

Fashion supply chains are intricate networks of producers, manufacturers, distributors, and retailers. Grasping the multistage process—from cotton fields to closet hangers—reveals hidden costs behind every garment. Behind the glossy store displays lie uncomfortable truths: underpaid laborers, deforestation for fabric production, and ethical gray zones most shoppers never consider.

True transparency requires brands to disclose material origins, factory conditions, and carbon emissions at each production phase. Without this radical openness, consumers unwittingly support systems that harm both people and planet.

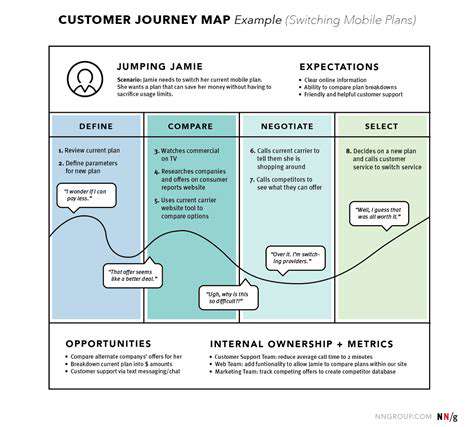

Traceability: Mapping the Journey of Your Clothes

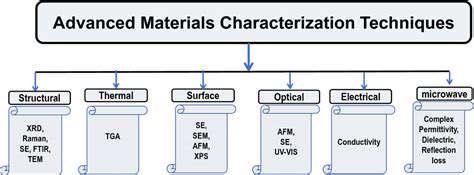

Modern traceability systems act like forensic tools for apparel, revealing a garment's complete backstory. Advanced tracking can pinpoint whether the cotton came from Uzbekistan's fields or Turkey's mills, whether dyes polluted rivers in Bangladesh, or if workers received fair compensation. This forensic-level visibility transforms how we assess value in clothing.

Supply chain mapping exposes systemic weaknesses—like unauthorized subcontracting that enables child labor or regions where water-intensive farming depletes local aquifers. Knowledge empowers change.

Ethical Sourcing and Labor Practices

Ethical sourcing demands more than minimum wage compliance—it requires humane treatment, collective bargaining rights, and workplace dignity. The reality? Most fast fashion workers earn less than 1% of a garment's retail price while facing unsafe conditions.

Credible transparency initiatives involve surprise factory inspections, worker interviews without management present, and public reporting of violations. Only through such rigorous verification can brands claim true ethical production.

Environmental Impact Assessment: Measuring Sustainability

A single cotton t-shirt's lifecycle consumes 2,700 liters of water—enough drinking water for one person for 900 days. Transparency in environmental reporting should quantify:- Water consumption per garment- Microplastic shedding potential- End-of-life biodegradabilityWithout standardized metrics, sustainable fashion remains an empty marketing term.

Transparency Initiatives: Empowering Consumers

Trustworthy certifications like Fair Trade Certified™ and B Corp provide third-party validation of ethical claims. Blockchain-based systems like TextileGenesis™ create tamper-proof records of material provenance. These tools finally enable voting with your wallet based on facts rather than greenwashed marketing.

Technology Solutions for Supply Chain Visibility

Blockchain's immutable ledgers now track organic cotton from Indian farms to European warehouses. AI analyzes satellite imagery to monitor deforestation near viscose factories. RFID tags log real-time transport conditions for temperature-sensitive dyes. Such innovations make opaque supply chains auditable in unprecedented ways.

Consumer Responsibility and Demand for Change

The $1.5 trillion fashion industry won't reform until shoppers demand accountability. Key actions:- Research brands' supply chain disclosures- Support legislation like the Fashion Sustainability Act- Choose quality over quantityCollective pressure forced brands to disclose factory lists after the Rana Plaza disaster—proof that informed consumers drive progress.

Mapping the Journey: Tracing Garments Through the Supply Chain

Mapping the Journey: Unveiling the Essence of Garme

Garme represents cultural DNA preserved through generations yet constantly evolving. Its survival through colonization, industrialization, and globalization proves cultural resilience can coexist with adaptation.

Unraveling the Threads: Key Influences on Garme

Portuguese trade introduced indigo dyes. British railroads enabled wider distribution. Each foreign interaction left marks—sometimes subtle as stitching variations, sometimes profound as new ceremonial uses.

Exploring the Landscapes of Garme: A Cultural Geography

The Kashmir variant uses pashmina wool, while coastal communities incorporate seashell embellishments. These regional adaptations demonstrate how environment shapes cultural expression.

The Legacy of Garme: A Future Perspective

Young designers now blend augmented reality with traditional motifs. This symbiosis of ancient craft and modern tech charts a viable path forward.