Why Ethical Sourcing is Non Negotiable in Fashion

Fast Fashion's Footprint

The environmental ledger of fast fashion reveals compounding deficits. Each synthetic garment sheds microplastics throughout its lifecycle, from washing machine effluent to landfill leachate. Natural fibers bring different burdens - conventional cotton farming consumes 2.5% of global arable land while using disproportionate pesticide volumes.

Water Pollution and Resource Depletion

Textile processing contaminates vital water sources with heavy metals and persistent organic pollutants. In manufacturing hubs, adjacent communities suffer elevated cancer rates and birth defects linked to factory effluent. Meanwhile, aquifer depletion for water-intensive crops like cotton creates agricultural crises in vulnerable regions.

Greenhouse Gas Emissions

The carbon calculus includes more than transportation. Synthetic fiber production relies on petroleum derivatives, while fabric finishing releases potent greenhouse gases like nitrogen oxides. Even natural materials carry hidden climate costs - wool production generates surprising methane volumes through livestock digestion.

Waste Generation and Landfill Impact

Post-consumer textile waste represents just part of the problem. Pre-consumer waste - fabric scraps, defective items, and unsold inventory - may equal or exceed what reaches consumers. Fast fashion's rapid trend cycles ensure most donations become landfill fodder rather than finding second lives.

Chemical Exposure and Human Health

Chemical risks extend beyond factory workers. Residual processing chemicals in finished garments can trigger dermatological reactions in sensitive wearers. The industry's reliance on PFAS for stain resistance introduces persistent environmental toxins through routine laundering.

The Impact on Biodiversity

Fashion's ecological web includes collateral damage to pollinators from pesticide-laden cotton fields, marine ecosystem disruption from microplastic pollution, and habitat loss from fiber crop monocultures. These interconnected impacts demonstrate why sustainable fashion requires holistic environmental accounting.

Transparency and Accountability: Building Trust in the Supply Chain

Importance of Transparency

True supply chain transparency requires moving beyond performative disclosure. Leading brands now implement third-party verified mapping of tier-2 and tier-3 suppliers - the hidden network of subcontractors where most violations occur. This granular visibility enables targeted improvements rather than superficial compliance.

Accountability Mechanisms

Effective accountability requires enforceable contracts with financial penalties for non-compliance, not voluntary codes of conduct. Worker-driven monitoring programs that bypass corporate filters provide more reliable oversight than traditional auditing systems vulnerable to manipulation.

Enhancing Trust through Ethical Practices

Trust-building measures include public remediation plans for identified violations, rather than simply cutting ties with problematic suppliers. Living wage commitments with defined timelines and verification protocols demonstrate seriousness beyond aspirational statements.

The Future of Fashion: A Commitment to Ethical Practices

Sustainable Practices in Fashion

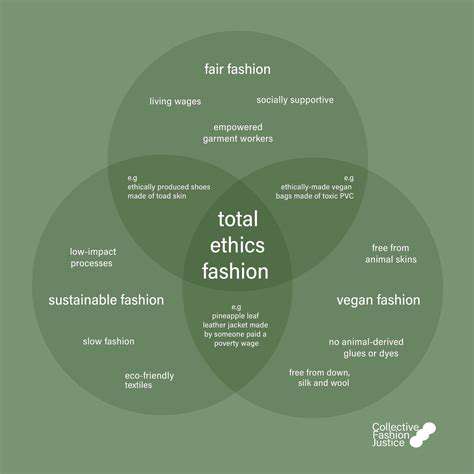

The most promising innovations address multiple challenges simultaneously. Agricultural waste upcycling converts pineapple leaves or mushroom roots into viable leather alternatives while creating new income streams for farmers. Such solutions exemplify the circular economy principles needed to replace extractive models.

Technological Advancements in Design and Production

Digital product passports incorporating blockchain technology could revolutionize transparency by documenting each garment's journey from fiber to retail. These immutable records would finally enable credible claims about ethical sourcing and environmental impact.

Personalization and Customization

Mass customization platforms using AI-assisted design and on-demand manufacturing could dramatically reduce overproduction waste while satisfying consumer desire for uniqueness. This model represents a potential middle ground between fast fashion's accessibility and slow fashion's values.